Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

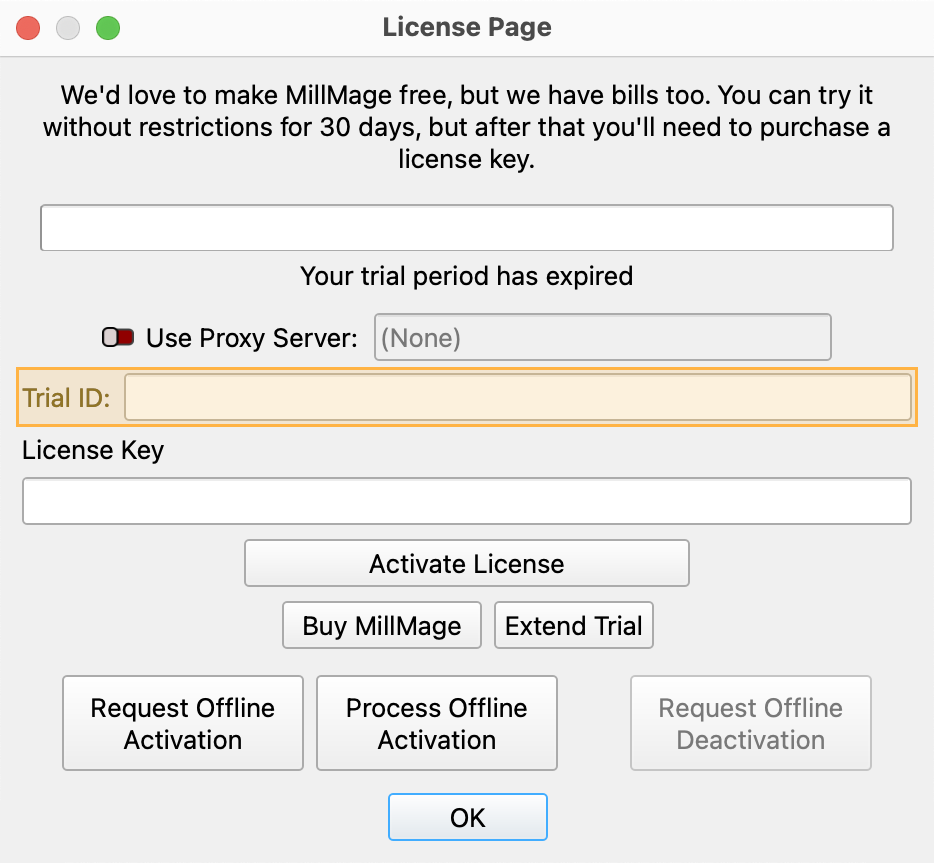

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Assigning Operations

To tell your router how to carve designs in your Workspace, you'll need to create and assign operations through the Operations Window. From the Operations Window, you can also control the order the machine processes the operations, adjust an abbreviated set of settings for each operation, and more.

You can toggle individual operations on or off, export your project into GCode files, and when multiple operations are enabled, chain the operations together to send them to your machine sequentially.

Tip: Chain Operations With the Same Tool

Reduce job time by executing operations one after another, if the same tool can be used for each one.

You can assign the same shape or group of shapes to multiple operations with different depths, speeds, feeds, and actions; and you can assign multiple operations with different depths, speeds, feeds, and actions to a shape or group of shapes.

Creating Operations¶

To create an operation, select New Operation in the Operations Window and choose an operation from the dropdown menu.

Once you've selected an operation, the Operation Settings Editor will open, where you can select a tool and apply a number of operation-specific settings.

Note

Any shapes currently in your selection when you click New Operation will automatically be Assigned to that operation.

Common Operations

Pocket¶

Pocket operations tell your router to clear an area that falls within the outlines of designated vector graphics.

If individual, non-overlapping vector graphics are assigned to a Pocket operation, the entire area within each graphic will be cleared.

If multiple vector graphics are assigned to the same Pocket operation, and one of the graphics is inside another, the area between the outlines of both will be cleared.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape in order to determine the area to clear, Pocket mode only works with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Profile¶

Profile operations tell your router to follow a path defined by the outlines of vector graphics. You can choose to set the path to the outside, inside, or directly centered on the outline.

The outcome of a Profile operation depends on your choice of tool and settings. You can use tools with special geometry to achieve interesting carving effects, or use a standard End Mill and a sufficient Final Depth to cut through your stock.

Advanced Operations

Rest Pocket¶

Rest Pocket operations tell your router to clear the remainder of an area that has already been mostly cleared by a separate Pocket operation. The area cleared by the Rest Pocket operation is defined as the space within the outlines of designated vector graphics that cannot be reached by a specified larger clearing tool.

In the screenshot below, both shapes are assigned to a Pocket operation and a Rest Pocket operation. In the Preview simulation, the red area indicates a Pocket operation performed by a ¼" tool. The blue area indicates a Rest Pocket operation performed by a smaller, ⅛" tool.

Using a Rest Pocket operation after a Pocket operation allows you to clear the larger area with the ¼" tool more quickly than you could with the ⅛" tool, while using the ⅛" tool to clear the narrow areas along the left and right sides of the shapes that the ¼" tool could not reach.

Warning

For the purposes of our demonstration, we've shown the Pocket and Rest Pocket operations running in direct succession, but you will need to perform a tool change in between running each operation.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape in order to determine the area to clear, Rest Pocket mode only works with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Chamfer¶

Chamfer Profile operations cut angled edges along the sides of material with sharp corners. The chamfered edge follows a path defined by the outlines of vector graphics in your project.

You can choose to apply a Tip Offset that tells MillMage to adjust the path to the outside or inside. MillMage will calculate the necessary depth to lower the bit in order to achieve a specified Chamfer Width, given the Tip Offset applied.

Applying a Tip Offset engages a greater portion of the effective cutting area of your V Bit than will be utilized if you do not apply an offset.

Note

You must select a V-bit for use with your Chamfer Profile operation. See Tool Library for information on creating and adding tools to your library.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape in order to determine the direction in which to apply the Tip Offset, Chamfer Profile mode only works with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Dogbone Slot¶

Dogbone Slots are a special type of Pocket operation that carves extra space at the corners of assigned shapes.

The extra space allows the slot to accommodate inserted pieces with sharp corners that would not otherwise fit if the slot had the arced corners characteristic of a standard Pocket operation.

Selecting the correct style of slot can conceal or minimize the amount of the slot that is visible when the pieces are joined together.

Assigning shapes to a Dogbone Slot operation leaves the original geometry in your Workspace unchanged — you'll only see the difference when you Preview or Start a job.

Note

Only rectangular shapes are valid for use with Dogbone Slot operations. The longer side of the rectangle must exceed the shorter side in length by at least 1 mm.

-

Both of these rectangles are identical. The top is assigned to a Dogbone Slot operation, while the bottom is assigned to a Pocket operation. -

Although the geometry of the shapes in the Workspace remains unchanged, MillMage will tell your router to carve a slightly altered area, expanding the corners. -

The outline of a standard Pocket is represented in black, and a rectangular insert is represented in red. Notice how the corners of the red insert are outside the arcs at the Pocket's corners — it won't fit. -

With the extra carved areas applied by the Dogbone Slot, there is now enough space to accommodate the corners of the rectangular insert — it will fit.

Drill¶

Drill operations tell your router to carve in a straight down motion. Depending on the type of the Drill operation and your settings, you can command your router to carve a hole cleanly through your material, mark a spot on the material, or bore a Countersink hole into its surface.

Drill operations are always located at the center of the individual shapes they are assigned to, regardless of the size of the shape. In other words, if you assign a Drill operation to a circle, the location of the carving will be the same regardless of whether the circle has a 5 mm diameter or a 50 mm diameter, provided the center of each circle is the same. Assigning non-circular shapes to Drill operations will result in a drilling operation in the center of the shape's selection box.

Inlay Female¶

Female Inlays are a special type of Pocket operation that allow you to specify an Allowance value that increases the area to be carved by your router, without alterning the original geometry of your project.

Female Inlay operations automatically produce pockets with rounded corners, to accomodate inlays that also have rounded corners.

Slightly increasing the size of the carved area allows you to more easily inlay fitted parts into the pocket. You can use Male Inlay operations in conjunction with Female Inlays to create parts that fit together snugly but without difficulty.

As with standard Pockets, Female Inlay operations tell your router to clear an area that falls within the outlines of designated vector graphics. If a single vector graphic is assigned to a Female Inlay operation, the entire area within that graphic will be cleared.

If multiple vector graphics are assigned to the same Female Inlay operation, and one of the graphics is inside another, the area between the outlines of both will be cleared instead.

MillMage will also adjust output intelligently, shifting the inner and outer paths in opposite directions, so the size of the final pocket is increased by the specified Allowance in both directions.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape in order to determine the area to clear, Pocket mode only works with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Inlay Male¶

Male Inlays are a special type of Profile operation that permit you to specify an Allowance value that decreases the size of the object to be cut, without altering the original geometry in your project.

Male Inlay operations automatically produce cut paths with rounded corners, so the resulting parts will fit within the rounded corners of an area pocketed by your CNC.

You can use Male Inlay operations in conjunction with Female Pocket operations to create parts that fit together snugly but without difficulty.

As with standard profile operations, Male Inlays operations tell your router to follow a path defined by the outlines of vector graphics.

Unlike standard Profile operations, you may not select a Profile Side for Male Inlays. MillMage assumes the interior of your shape is the part you intend to inlay, and therefore the cutting path is always set to the Outside.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape to adjust the cutting path, Male Inlay operations only work with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Assigning Operations to Shapes¶

You can always Assign operations to additional shapes in your Workspace after you first create them.

- First select the shapes in your Workspace.

- Next click an operation in the list in the Operations Window to select it as well.

- Finally, click Assign Shapes.

Note

Any shapes that were previously assigned to the chosen operation will be unassigned, if they are not in your selection when you press Assign Shapes.

Need to add objects to an already assigned operation? Use the Select Shapes button in the Operations window to automatically select the objects assigned to that operation. Add or remove selected shapes by holding either the Shift or ++Ctrl++ key while clicking on the shape. Press the Assign Shapes button to assign the selected objects to the selected operation.

Operations and Layers¶

In MillMage, you can also assign graphics to colors/layers. If you're familiar with our sister software, LightBurn, you may be accustomed to using these colors/layers to differentiate each operation needed to complete a job.

However, in MillMage, layers don't have any effect on the output to your CNC, with one important exception.

If you enable Auto Use Layer in the Operation Settings Editor, you can automatically apply that operation to all shapes set to the chosen layer. Designate which layer by clicking the button to the right of the switch.

Note

When Auto Use Layer is enabled, you can still Assign Operations to graphics set to any other layer, as normal, but all graphics assigned to the chosen layer will also have the Operation applied to them.

Selected Operation Info and Quick Edits¶

In the bottom of the Operations Window, you can view or edit a limited set of information about the currently selected operation. The chosen tool is visible but not editable, while the Start Depth and Final Depth of the selected operation are both visible and editable here.

It's a good practice to review this information to quickly confirm tool selection before starting jobs. and to confirm or update the Start/Final Depths assigned.

Disabling and Enabling Operations¶

Toggle the switch in the Output column to determine which operations are active when you Preview, Start, or save a project in GCode format.

Rearranging Operations¶

By default, operations are performed by your machine in the order from top to bottom in which they are listed in the Operations Window.

To change the order of the selected operation in the list you can click and drag to change its position, or select an operation and click the up and down buttons in the window.

Best Practice: Preview Operations

Always use the Preview window before starting any job to:

- See the order in which operations will be completed

- Check that your CNC machine will do what you expect and move collision-free

- Estimate how long a job will take

Next Steps¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.