Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

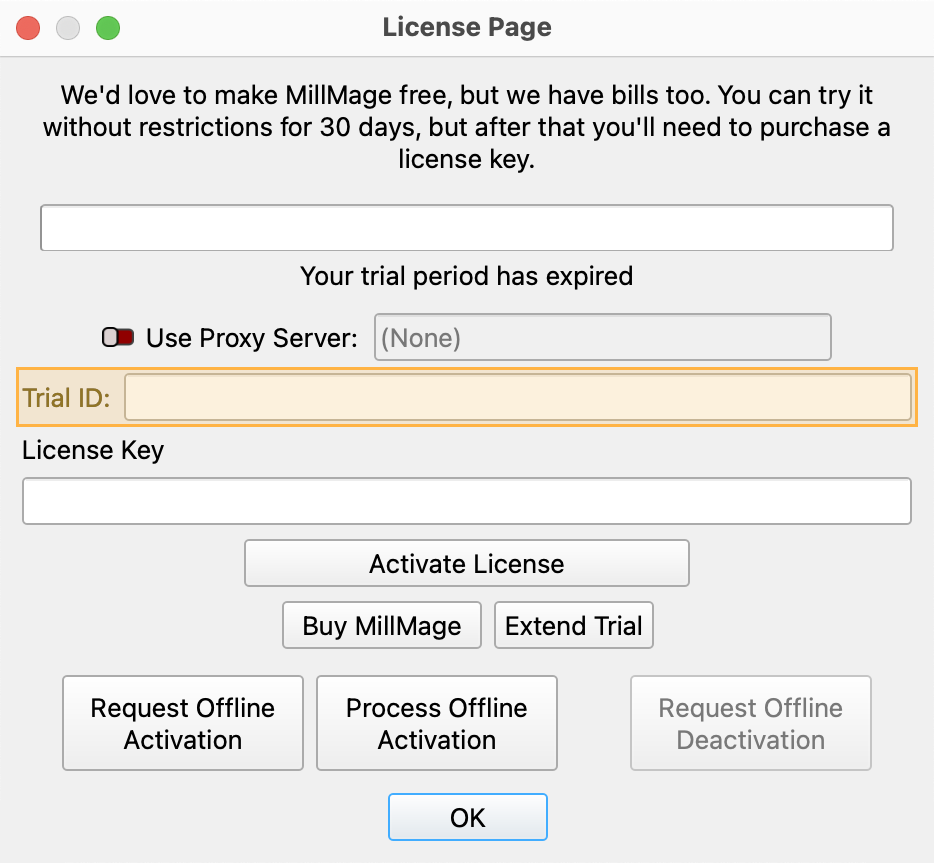

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Tool Length Probing

This guide covers using a Tool Length Probe with the Probing Wizard to automatically calculate the length of an installed tool to determine and apply the tool offset needed to maintain the project Z axis zero point.

Using a probe to do this isn't strictly necessary for basic CNC work – you can manually re-zero your Z axis zero after changing a tool, but probing can perform that process automatically, and more quickly.

A tool length probe is especially helpful when a project's Z Axis Zero Point is set to Top and has been machined away during previous operations, and can aid in project recovery when the spindle, router, or tool has slipped and been re-secured, but potentially in a different position.

To follow this guide, you'll need a CNC machine with a tool length probe located within the travel area of the machine. The probes may be built into the machine or may need to be installed as a separate accessory. Refer to and follow your CNC manufacturer's instructions when installing a tool length probe.

How Tool Length Probing Works¶

Tool length probes vary in type, location, and material, but typically work the same: your CNC will jog/move the tool over the position of a probe in your CNC's work area, then lower the tool until it makes contact with the probe, sending a signal to the machine's controller to calculate and establish the new tool Z axis zero point.

Setting Up a Tool Length Probe¶

Set the position and motion parameters of your tool probes in the Probe Configuration window. If you have already defined your probing settings, you can skip ahead to Activating Tool Length Probing.

1. Find the X and Y Axis Tool Length Probe Location¶

Use the Move Window to determine the tool length probe location.

Warning

Make sure that before you start probing for tool length that the spindle or router collet is tight and the tool secure. The spindle or router must be off and not rotating.

- Close the Probing Wizard if open

- Select the Move Window

- Use the jogging buttons to move and roughly center the tool above the probe location

- Note the machine X and Y Axis coordinates in the Move Window, labeled Tool Position (M)

2. Open Probe Configuration Window¶

Open the Probe Configuration window to define the parameters of your tool length probe by selecting either:

- CNC Tools → Probe Settings

- CNC Tools → Probing Wizard → Manage Probe Configuration

- Move Tab → Probing → Manage Probe Configuration

3. Update Settings¶

Select Tool Length Probe to open the Tool Length Probe settings panel. Click in the image below for more details on each setting.

Position X and Position Y¶

- Position X is the location in machine coordinates of the tool length probe along the X axis (left/right).

- Position Y is the location in machine coordinates of the tool length probe along the Y axis (towards/away).

Search Z¶

Search Z is the maximum distance the tool will move downward when seeking the tool length probe. Set the Search Z distance to the length of the Z axis travel. Refer to your CNC manufacturer documentation for your machine's values.

Fast Probe Feed and Precise Probe Feed¶

- Fast Probe Feed is the initial speed at which the tool will search for the tool length probe. This can be fairly fast, depending on your risk tolerance.

- Precise Probe Feed is the lower speed at which the tool will search for the probe after initial contact. This movement will be a very short distance and should be kept to a fairly low speed for accuracy.

Precise Probe Distance and Backoff Distance¶

- Precise probe distance is the distance the tool will slowly move towards the probing engagement point, set to 3.5 mm by default.

- Backoff distance is the length of movement the tool will slowly back away from the probing engagement point, set to 1.5 mm by default.

4. Save Settings¶

Select OK to save the settings. Select Yes if prompted, to overwrite the previous Tool Length Probe Custom GCode entry in Device Settings. The Probe Settings window will close when saved.

Activating Tool Length Probing¶

Warning

Make sure that before you start probing for tool length that the spindle or router collet is tight and the tool secure. The spindle or router must be off and not rotating.

1. Ensure Spindle or Router is Powered Off¶

Always power off your CNC router or ensure that the spindle is not rotating before executing the probing process. An active spindle or router tool can damage the tool length probe, the tool, and machine and can lead to personal injury.

2. Install Desired Tool¶

Install the desired tool into the CNC router or spindle, ensuring that the collet has been tightened enough to securely hold the tool.

If the CNC router or tool is not securely installed, the Tool Length Probing process may fail or the tool may move, leading to inaccurate results.

3. Open Probing Wizard¶

Open the Probing Wizard by selecting CNC Tools → Probing Wizard, or by clicking the Probing button in the Move window.

4. Select Tool Length Probe¶

Click on Tool Length Probe to open the Tool Length Probe window.

5. Start Tool Length Probing¶

PINCH DANGER

Keep fingers and hands away from the probing puck and/or tool during the probing process.

The CNC machine will keep moving the tool towards the puck or probe sensor until the machine is powered off, stopped by a hardware Emergency Stop, or successfully completes contact with the puck or probe.

Select Execute Tool Length Probe.

6. Monitor Probing Process¶

Once executed, the Probe Wizard will automatically:

- Move the tool to the user-defined probe location along the X and Y Axes

- Home the Z Axis

- Move the tool down the user-defined Search Z distance at the Fast probe feed speed on the Z axis until the probing switch or sensor is triggered

- Move the tool up away from the probe

- Approach the probe again, this time at the slower Precise probe feed speed until the probing switch or sensor is triggered

- Set the new tool length and the new Z Axis zero point

7. That's it!¶

You are now ready to run the operations in your project that use the tool you installed. Check the operations listed in the Operations window and turn on related operations that match your installed tool and turn off the remaining entries that do not match. Remember to run the Tool Length Probe again after each additional tool change within your project.

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.