Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

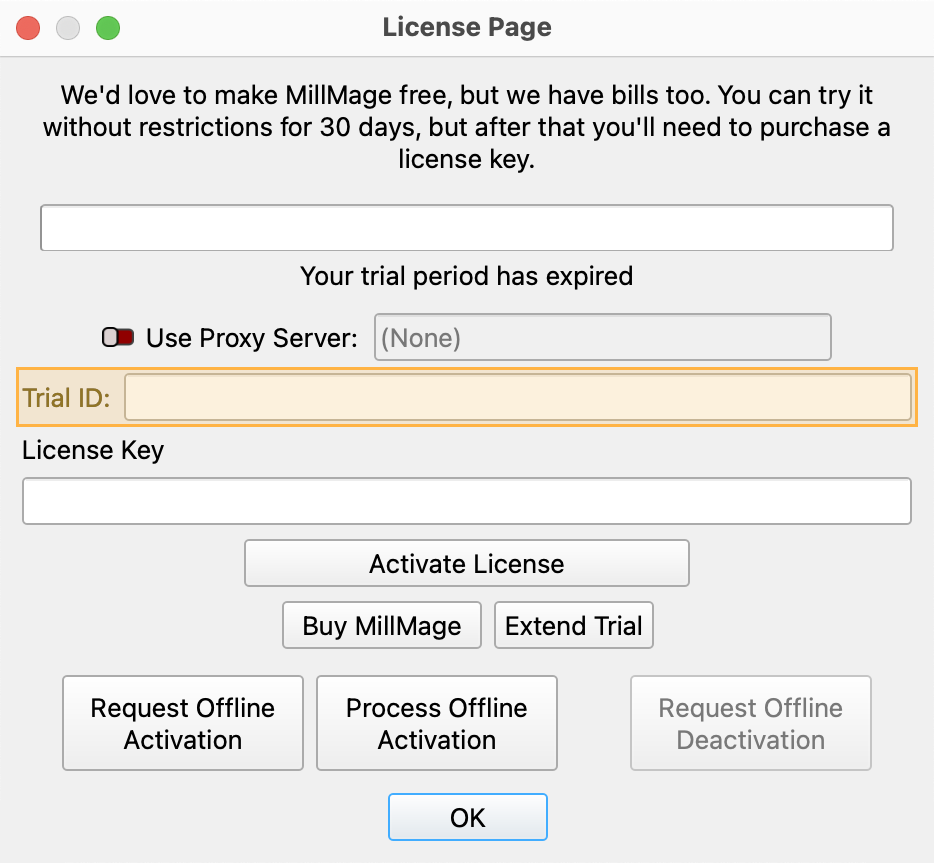

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Chamfer

Chamfer Profile operations cut angled edges along the sides of material with sharp corners. The chamfered edge follows a path defined by the outlines of vector graphics in your project.

You can choose to apply a Tip Offset that tells MillMage to adjust the path to the outside or inside. MillMage will calculate the necessary depth to lower the bit in order to achieve a specified Chamfer Width, given the Tip Offset applied.

Applying a Tip Offset engages a greater portion of the effective cutting area of your V Bit than will be utilized if you do not apply an offset.

Note

You must select a V-bit for use with your Chamfer Profile operation. See Tool Library for information on creating and adding tools to your library.

Open vs. Closed Shapes

Because MillMage must determine the inside and outside of a shape in order to determine the direction in which to apply the Tip Offset, Chamfer Profile mode only works with shapes that are closed. A shape is closed when it is a complete, continuous loop whose start and end points are the same. When a shape's start and end points are different, it is open.

See Open vs. Closed Shapes for more information on the difference between open and closed shapes.

Chamfer Mode Settings¶

Click any option in the image below to jump directly to the relevant section for that option, or scroll down for a list of options and descriptions.

Sections that have special settings for Chamfer operations are listed just below, while common settings that apply similarly to most or all other types of operations are listed toward the bottom.

Note

For information on options that are unique to other types of operations, see Other Operations, below.

Profile Side¶

Profile Side tells MillMage which direction to shift that path it command your router to travel while carving the chamfered edge, relative to the original vector graphics in your project.

-

Inside shifts the path MillMage tells your router to travel in toward the center of vector graphics.

-

Outside will shift the path MillMage tells your router to travel out away from the outlines of vector graphics.

In general, you'll want to shift the path away from the existing edge you'll be carving an angled edge into. In other words, if you are carving a chamfer into an outer edge of your material, choose Outside. If you are carving a chamfer into a inner rim of your material, choose Inside.

The distance MillMage shifts the path relative to the original graphics is determined by the Tip Offset value you enter.

Pattern Preview¶

The Pattern Preview depicts the path (in purple) your router will travel on an example shape, relative to the original contour of the graphic (shown as a dotted green line), as determined by your current Side selection.

Depths and Entry¶

Equation Support and Automatic Unit Conversion

The Depths and Entry/Steps fields in the Operation Settings Editor support equations and automatic unit conversion.

For example:

-

To cut to a final depth of ¼ in, type

1/4in the Diameter field, then click in another field, and MillMage will convert to the value to0.75.Addition (

+), subtraction (-), and multiplication (*), are all also supported. -

If your display units are set to metric but you've taken measurements in imperial, you can enter

1/4 inand MillMage will convert the value to6.350 mm. This works in reverse as well, converting metric units to imperialMultiple notations are supported, including

ft,',", andmm.

Start Depth¶

Determines the Z height at which your router will begin carving.

A value of 0 means it will begin at the top of your material — any value greater than 0 will tell your router to begin carving below the surface of the material.

Tip Offset¶

The Tip Offset value determines how far MillMage will shift your tool to the Inside or Outside of your shapes.

MillMage will automatically calculate the necessary depth to lower your tool to, in order to carve a chamfered edge of your specified width.

Measured From¶

Measured From determines whether the Tip Offset is applied relative to Bit Tip or Contact Edge.

Chamfer Width¶

Specifies the width of the chamfered edge. MillMage will automatically determine the correct depth to plunge your tool to achieve this width.

Warning

The maximum Chamfer Width value is half your tool's diameter.

If you enter a value that is too wide for your tool to carve, MillMage will send a warning message when you try to Preview or Start a job.

If you choose to proceed without adjusting your settings, the Chamfer Profile operation will not output appear in the Preview, or output to your machine.

Depth Per Pass¶

Specifies the depth of material to be cleared with each pass of your router.

MillMage will calculate the required number of passes at your specified depth to achieve a chamfered edge of your chosen width.

Entry Type¶

Entry Type controls the motion of your router as it lowers into your material.

For Zig Zag Ramp and Plunge entries, the router lowers to the depth set in the Depth Per Pass, as it begins carving.

For Spiral entires, rather than lowering to a set height before proceeeding to the next pass, the router is continually lowered in a spiral pattern for the duration of the operation.

Plunge¶

Lowers the router straight down along the Z Axis into the material, before the router moves in X or Y. The same Plunge movement is repeated as the router lowers for each subsequent pass.

Zig Zag Ramp¶

Lowers the router along the Z Axis into the material, while also making lateral movements along the X or Y axis, meaning the tool enters at an angle — the exact angle is determined by the Ramp Angle setting.

The same Zig Zag movement is repeated as the router lowers for each subsequent pass.

The router makes a straight down movement in Z before beginning the ramped entry.

Ramp Angle¶

Controls the angle at which your tool will enter the material, if you’ve selected Zig Zag Ramp as your Entry Type.

Spiral¶

Constantly lowers the router into the material in a spiral pattern in X, Y, and Z, for the duration of the Profile operation.

The router makes a straight down movement in Z before beginning the spiral entry.

Tabs / Bridges¶

Tabs are small sections of cuts that the machine is commanded to skip, used to prevent objects from coming free from the base material during cutting.

Warning

Proper use of tabs is essential for preventing objects from flying out of your material at high speeds, resulting in damage to your project, machine, or self.

When sized appropriately, the tabs can be broken with minimal force and the objects removed from the material after the job is finished cutting. You may need to use a wood chisel to remove the tabs, or to sand down remnants of the tabs after removal.

You can create tabs manually using the Add Tabs tool, or MillMage can generate them automatically using the Tab Wizard found in the Operations Window.

Enable / Disable¶

The switch next to Tabs / Bridges controls whether tabs are enabled for the layer.

Switch Tabs / Bridges off to disable tabs. Tab settings and placement are not lost when this switch is turned off, and are restored exactly as they were if it is switched on again.

Tab Type¶

Use the Tab Type dropdown menu to select from one of three options.

Full Retract¶

Tells your router to lift back above the surface of your material when skipping over tabs. This results in tabs that are completely untouched by the router, and flush with the surface of the material.

Partial Retract¶

Allows you to specify a Tab Height for your tabs. Your router will continue carving all of your material until it reaches the specified height. After that height, when the router reaches parts of a path designated for tabs, it will retract to the specified Tab Height and then skip over tabs.

For example, if your stock is 10 mm thick, and you set a Tab Height of 5 mm, your router will engrave 5 mm of material above each tab, then skip the tabs for the last 5 mm of depth.

Ramp¶

Works similarly to Partial Retract, but instead of retracting to the specified Tab Height when it reaches a tab, your router will continue carving at an angle, moving upward until it reaches the Tab Height.

The angle of the Ramp is determined by the relationship between Tab Size and Tab Height. Longer tabs and lower heights can accommodate more gradual angles than shorter tabs and greater heights.

Tab Size¶

Tab Size defines the total length of each tab, in the currently configured system unit type (mm or inch). The router will skip carving for this distance.

Tab Height¶

Tab Height is only available when Tab Type is set to Partial Retract or Ramp.

See above for more information on the interaction of this setting with those Tab Types.

Common Settings¶

Click here for information on settings that apply similarly to all types of operations

Name¶

Use this field to edit the display name of the operation in the Operations Window. By default, all operations will be named according to their type.

Paint Color¶

Click the Paint Color button to open the Select Color window, which controls the color by which the operation will be indicated in the Preview window, if Show paint colors is enabled.

You can choose from a number of Basic Colors presented at the top left of the window, or create a custom color.

To create a custom color:

-

Press Pick Screen Color to hover your cursor over any color on your screen. Click to select the color you're hovering over.

-

Use the color gradient and shading slider at the top right.

-

Adjust numeric or hexidecimal values at the bottom right to create a custom color.

-

After creating a custom color, click Add to Custom Colors to save it for future use.

Click OK to apply the color to your operation, or Cancel to exit the window thout applying the color.

Output¶

Controls whether the operation will be sent to your CNC when you Preview your project, press the Start button in the Job Control Window, or save your project in GCode format.

Auto Use Layer¶

Enable this switch to automatically apply this operation to all shapes set to a given layer. Designate the layer by clicking the button to the right of the switch.

Note

When Auto Use Layer is enabled, you can still Assign Operations to graphics set to any other layer, as normal, but all graphics assigned to the chosen layer will also have the Operation applied to them.

Tool Setup¶

Select Tool¶

Press the Select Tool button to open your Tool Library and select a tool to assign to the operation.

MillMage will automatically filter for appropriate tools for the type of operation you've selected. Some operations require specific tool geometries — if a tool's geometry is not appropriate for the type of operation you've selected, it will be unlisted and not selectable.

Tool Information¶

The remaining fields in this section display information about your selected tool, as entered in the Tool Library.

Tool Name¶

The name you gave the chosen tool in the Tool Library.

Diameter¶

The diameter of the cutting edge of your tool.

Cut Length¶

The length of the cutting edge of the chosen tool, from the top to the bottom of all flutes.

# of Flutes¶

The number of flutes on the chosen tool.

Feeds and Speeds¶

The Feeds and Speeds saved to a given tool from your Tool Library are automatically entered in the Operation Settings Editor when you select that tool.

To enter speeds in units other than what's set in Device Settings, enter the measurement including in/" or mm to specify the units you want. MillMage will automatically convert to the appropriate units as shown in the example below.

What Feeds and Speeds should I use?

The proper Feed and Speed settings depend on your tool, machine, material, and use case. In short: there's no easy answer to that question.

For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

Feed Rate¶

Controls the speed at which your CNC will move laterally (along the X and Y axes) during operations.

Ramp Rate¶

Controls the speed at which your CNC will move vertically (along the Z Axis) during ramp movements.

Spindle Speed¶

Controls the speed at which your router will rotate your tool.

Note

Not all CNCs allow Spindle Speed control through software. Some have routers which must be adjusted manually.

Plunge¶

Controls the speed at which your CNC will move vertically (along the Z Axis) during plunge movements.

Chip Load¶

The Chip Load calculation shows the thickness of material removed by each cutting edge of a tool, during a single revolution of the spindle.

Chip Load = Feed Rate / (Spindle Speed (RPM) x # of Flutes)

The optimal Chip Load varies according to your tool and material. For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

Excessively low Chip Loads produce dust, wear out bits more quickly, and risk overheating the tool and burning the edges of cuts. Excessively high Chip Loads produce chips that clear inefficiently, and may overstress and break the bit.

Vacuum and Coolant¶

Enable Vacuum¶

Enable this setting to automatically turn on your vacuum system when this operation begins.

This option requires a vacuum system that is connected to your CNC's controller.

Enable Coolant¶

Enable this setting to automatically turn on your coolant system when this operation begins.

This option requires a coolant system that is connected to your CNC's controller.

Other Operations¶

All types of operations are listed below. Select an operation to learn more about the settings available for that type of operation.

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.