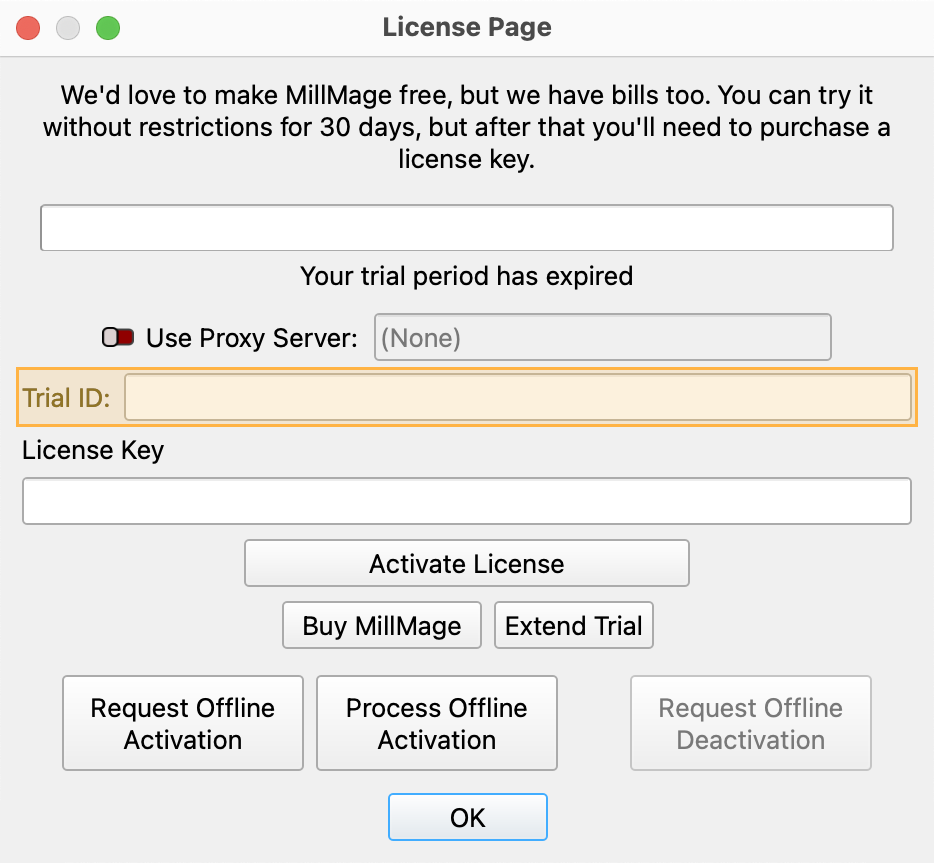

Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

CNC Types

Every CNC Machine is Different

CNC cutting and engraving performance, quality, and speed is highly machine & user-dependent. Beginners are advised to familiarize themselves with their CNC manufacturer user guide and manual prior to using a CNC machine with MillMage.

How a CNC Project is Made¶

To understand the parts each of the characteristics play, let's briefly touch on how a project goes from idea to physical product.

A design is created by a user in design software, and turned into machine instructions (code) through a control software.

MillMage operates as both a design and control software.

The instructions are delivered to a computer within the CNC machine called a controller. The controller translates the instructions into electrical signals that control the machine's motion system. The movement of the motion system delivers the CNC tool to the directed locations on the material stock.

See the Example MillMage Workflow in our Getting Started guide for more details.

Controllers and Firmware¶

The controller — and the firmware it runs — determines if a machine is compatible with MillMage.

A controller is essentially a computer within your CNC machine, and the firmware it runs determines the type of instructions it can translate into signals it delivers to the motion system. MillMage needs to know what type of firmware your device's controller is running to know what language to speak to the machine.

MillMage is currently compatible with and supports any CNC controller that uses standard RS-274 GCode, such as:

-

CAM and Control

- GRBL ≤1.1 Note: Compatible controllers will display [VER:1.1h.YearMoDate:] on console connect

- GRBL-STM

- grblHAL

- FluidNC

- Smoothieware (Labs feature testing)

-

CAM Only

- Mach3/Mach4

- LinuxCNC

- UCCNC

- Duet / RRF

- Masso

To connect to a GCode-based CNC machine, you'll need a standard MillMage License. If you're not sure what controller or firmware your CNC machine uses, consult your machine's manufacturer, or contact us at [email protected].

See the MillMage Fact Sheet for details on supported firmware and controllers

Motion System¶

MillMage supports CNC routers that move the tool along the X, Y, and Z axis. When facing your CNC machine, the

- X axis moves to the left and right

- Y axis moves forward and back

- Z axis moves down and up

Router or Spindle¶

Routers are generally less expensive than spindles, but operate more loudly and typically with less speed control. Spindles can offer software-controlled speeds and can be quieter when operating.

Tooling¶

CNC machines use a variety of different bits — also known as tools — to remove material from the project material stock. Larger tooling can remove a higher volume of material at a faster rate than smaller tooling, but at the cost of fine details, sharp inside corners and walls, and requires more machine rigidity. In general, use larger tooling with a shorter length instead of smaller or longer tools.

Common tools include:

-

End Mills have sharp edges that cut material as the tool rotates and moves laterally (along the X and Y axes).

The bottom of a standard End Mill is flat with sharp corners, resulting in flat clearings, and 90-degree corners at the edges of cleared areas.

Some End Mills have rounded corners meeting at a flat surface, and produce flat clearings, but sloped corners at the edges of cleared areas.

-

Ball Mills have completely rounded tips, resulting in rounded grooves with sloped edges where the tool has carved. Ball Mills are typically not used for clearing large areas.

-

V-Bits have angled tips that can create Chamfered edges, or angled grooves in material.

-

Drill bits have sharp tips to make vertical cuts (along the Z axis) into material.

-

Round-over bits have an inverted radius meeting at a tip, used to created rounded edges rather than sharp corners.

-

Scribe bits are used to precisely engrave a design by dragging its diamond coated tip over the surface of the material.

What Feeds and Speeds should I use?

The proper Feed and Speed settings depend on your tool, machine, material, and use case. In short: there's no easy answer that question.

For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

Connection¶

The connection is the method by which MillMage transfers the instructions to the machine. The current methods supported are as follows:

- USB Cable: limited to short distances, USB cables can be prone to errors, but are common in many machines. They don't work well when connected via hubs, splitters, or extension cables.

- Network/Data Cable: essentially an internet cable, these can be used over long distances and retain great signal strength.

- Saved to Network Drive: Save job files on mounted network storage locations.

- Saved to Physical Media: available on some GRBL controllers, this communication method is wireless.

Accessories¶

There are various accessories and non-critical or optional features available from manufacturers for machines. Some are explored below.

- Homing/limit switches: critical for accurate job-placement and replicability, these small buttons are triggered when the axis of a gantry machine reaches its "home" position, and allow the machine to position the tool according to a known physical location.

- Rotaries: allow cylindrical objects to be engraved. There are two main types, chucks and rollers. MillMage does not support rotaries at this time.

- Roller-based rotaries: carry an object by rotating wheels beneath it. This style of rotary is not suited to objects that aren't perfectly cylindrical or are prone to slipping, and are tricky to dial in for full-wrap engraves.

- Chuck-based rotaries: physically hold the workpiece in jaws, and rotate around a known axis by a known number of steps (pulses of the motor).

- Enclosures: another critical safety feature, appropriate enclosures protect a user from thrown chips, broken tooling, and even scrap.

Related Topics¶

- MillMage Fact Sheet

- Project Setup Edit

- Project Setup Wizard

- Workspace

- Operations Window

- Operations Setting Editor

- Move Window

- Workholding

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.