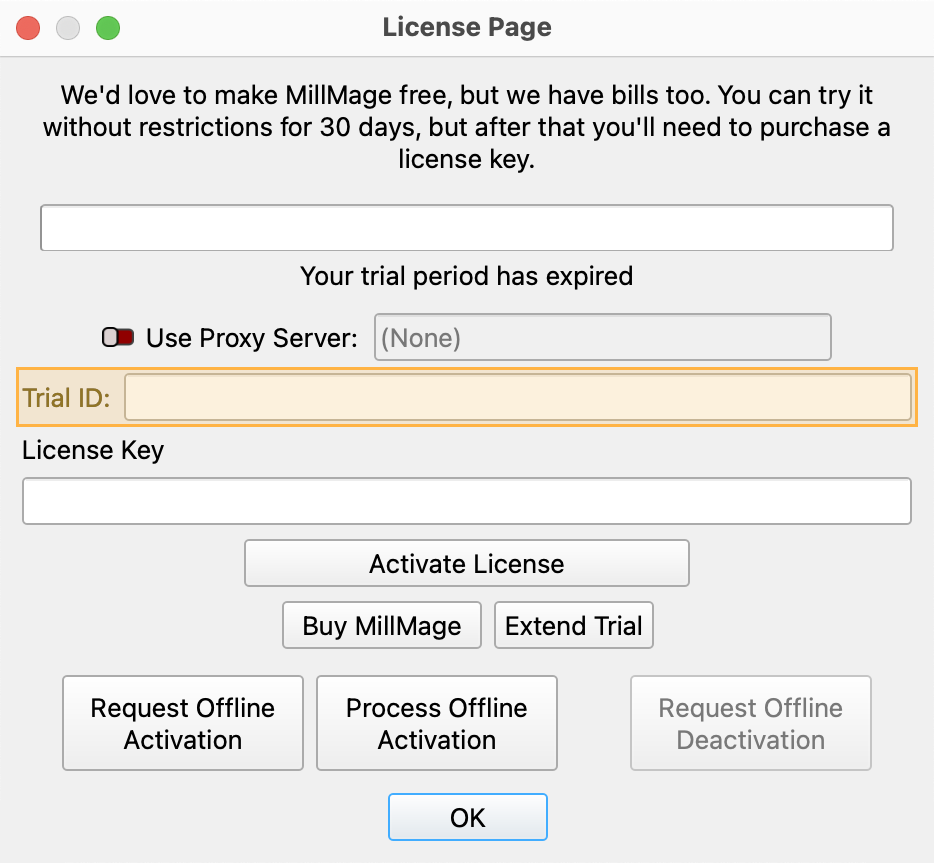

Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Controlling Your CNC Machine

Now that you've added a machine, set up a project, created a tool library, and assigned operations to your shapes, it's time to look at how to control your CNC machine using the Move and Job Control Windows.

Move¶

Use the Move Window to jog the tool around the work area, activate optional hardware features, home the axes, get tool position, establish project origins when zeroing out each axis, and move the tool to saved positions.

Start In MillMage, Move With MillMage

Always use MillMage to perform any movement, homing, or project zeroing/Workpiece Coordinate Offset setting after your CNC machine is powered on and has been homed to Machine Zero.

Movements or Work Coordinate Offset changes driven through hardware-based accessories like pendants or onboard jogging controls may cause unexpected machine behavior before, during, or after jobs.

Tool Position Display¶

The top of the Move Window displays the position of the tool in relation to both the Machine and Workspace Coordinate space.

Machine Position vs. Workpiece Position¶

MillMage displays the current tool position relative to two coordinate systems: Machine Coordinates and Workpiece Coordinates. The Position tab in the Move Window has a toggle to select which coordinate system to use for positioning.

- Machine Position is the position of the tool relative to the entire area of the machine. This coordinate system will be consistent regardless of the size or origin of the workpiece between projects.

- Workpiece Position is the position of the tool relative to the workpiece defined in Project Setup and by zeroing out the axes in the Move Window's Position. This coordinate system will vary between projects.

Zero Axes¶

Use the Zero Workpiece button to set the current position of the tool as the workpiece origin, or use Zero Workpiece X, Zero Workpiece Y, or Zero Workpiece Z to set zero for a single axis. Combined with Use Workpiece Coordinates, this lets you work in the same coordinate system used in your MillMage project.

Jog Tab¶

Use the elements in the Jog tab to manually move each axis, in different length increments. Click any option in the image below to jump to more information, or scroll down for a list of options and descriptions.

Use the Jog tab to command movement, including:

- Setting the jog speed

- Jogging the tool head along the X, Y, and Z Axes

- Set the X, Y, and Z Axis move distance between fine and large increments

- Toggling Fast Jog

Be careful when jogging!

Before jogging your machine, check the following:

- Your jog speed is set to an appropriate value for your machine.

- The jog interval is set to a reasonable value.

- The tool has a clear travel path.

Jogging Speeds¶

In general, the X and Y axis can be set to faster jogging speeds than the Z axis. Refer to your CNC manufacturer documentation for details. If you hear grinding, squeaking, or squealing, change the jogging speed until the movement sounds normal.

Jogging the X and Y Axis¶

To jog the X (left/right) Axis or Y (front/back) Axis:

- Set your XY Speed, either by entering a value or clicking one of the preset buttons.

- Set your XY jog interval under XY Distance. As with the jog speed, you can enter a value manually or use one of the preset buttons.

- Use either the jog arrows on the left side of the jog tab or the number pad on your keyboard to move the tool. The diagram included here shows the number pad controls.

Alternate Jogging Hotkeys

If your keyboard doesn't have a number pad, you can use the following shortcuts for jogging the X and Y axis:

- Jog Left: Alt/Option + Ctrl/Cmd + [

- Jog Right: Alt/Option + Ctrl/Cmd + ]

- Jog Forward: Shift + Ctrl/Cmd + ]

- Jog Backward: Shift + Ctrl/Cmd + [

Jogging the Z Axis¶

To jog the Z (up/down) Axis:

- Set your Z Speed, either by entering a value or clicking one of the preset buttons.

- Set your Z jog interval under Z Distance. As with the jog speed, you can enter a value manually or use one of the preset buttons.

- Use the up and down arrows to the left of Z distance to raise and lower the tool.

Position Tab¶

The Position allows you to home each axis of the CNC machine, retrieve and go to both workpiece and machine coordinates. Click any option in the image below to jump to more information, or scroll down for a list of options and descriptions.

Use the Position tab to:

- Zero out the X, Y, and Z Axis tool position to establish the workpiece origin.

- Get the X, Y, and Z Axis coordinates of the current tool position.

- View the coordinates of any point in the Workspace.

- Home the X, Y, and Z Axis.

- Move to saved positions.

Home Axes¶

Use the All button to command your CNC to execute a homing cycle on all axes, during which it moves toward the home position on each axis, seeking switches that activate when it hits the boundary.

Use X, Y, or Z to home X, Y, or Z Axis individually.

Get Coordinates¶

Use the Get All button to get the current X, Y, and Z coordinates. Depending on whether Use Workpiece Coordinates is enabled, this may be in either the Workpiece coordinate space or the Machine coordinate space. Use Get X, Get Y, or Get Z to get the current position in a single axis.

Go To Position¶

Click the Go To button to move the router to the coordinates in the X, Y, and Z input boxes next to the Go To buttons.

Use the Go To X, Y, and Z buttons to move the router to the coordinate in the box next to each button, on that axis only.

Use Workpiece Coordinates¶

Typically off by default, enable the Workpiece toggle to report the router's position in workpiece coordinate space — in other words, relative to the zero position you established on the workpiece.

Saved Positions¶

The Saved Positions dropdown displays a list of previously stored positions. Use Saved Positions for jogging to known locations in the work area — for example a specific corner or commonly used jig. Manage the contents of this list by clicking the Manage button.

For information on managing Saved Positions, see Managing Saved Positions.

Override Tab¶

The Override tab allows you to adjust travel speeds and spindle speeds while a job is in progress. Click any option in the image below to jump to more information, or scroll down for a list of options and descriptions.

Tool Travel Speed Override¶

Note

Each Override option adjusts settings as a percentage of the original values — not by absolute values.

Use these buttons to bump the travel speed up or down, or use the Reset button to return to the speed specified in GCode.

Spindle Speed Override¶

Use these buttons to bump the spindle speed up or down, or use the Reset button to return to the speed specified in GCode.

Control Optional Hardware Accessories¶

Start In MillMage, Move With MillMage

Always use MillMage to perform any movement, homing, or project zeroing/Workpiece Coordinate Offset setting after your CNC machine is powered on and has been homed to Machine Zero.

Movements or Work Coordinate Offset changes driven through hardware-based accessories like pendants or onboard jogging controls may cause unexpected machine behavior before, during, or after jobs.

In this section, you'll find controls for optional hardware accessories.

Probing¶

This button will open the Probing Wizard.

Coolant¶

Use this button to enable or disable coolant, if your machine has this capability.

Vacuum¶

Use this button to enable or disable a vacuum system, if your machine has this capability.

Spindle¶

Use this button to enable or disable the spindle at the speed set in RPM (Revolutions Per Minute), if your machine has this capability. If your CNC machines is equipped with a router, you will need to set your tooling rotational speed manually after referring to your router manufacturer's documentation for more information.

Units¶

Use the dropdown at the bottom of this window to change your control units betwen mm/s, mm/min, or in/min. Use the toggle to control whether your control units and design units are linked. For more on this, click the blue box below.

Design and Control Units

By default, control units — the units used for speed and distance when controlling your device — are linked with design units — the units used when designing in MillMage. Changing either one between millimeters and inches will automatically change the other.

To unlink the two types of units, use the Unit Linking Toggle in the Move Window.

Next Steps¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.