Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

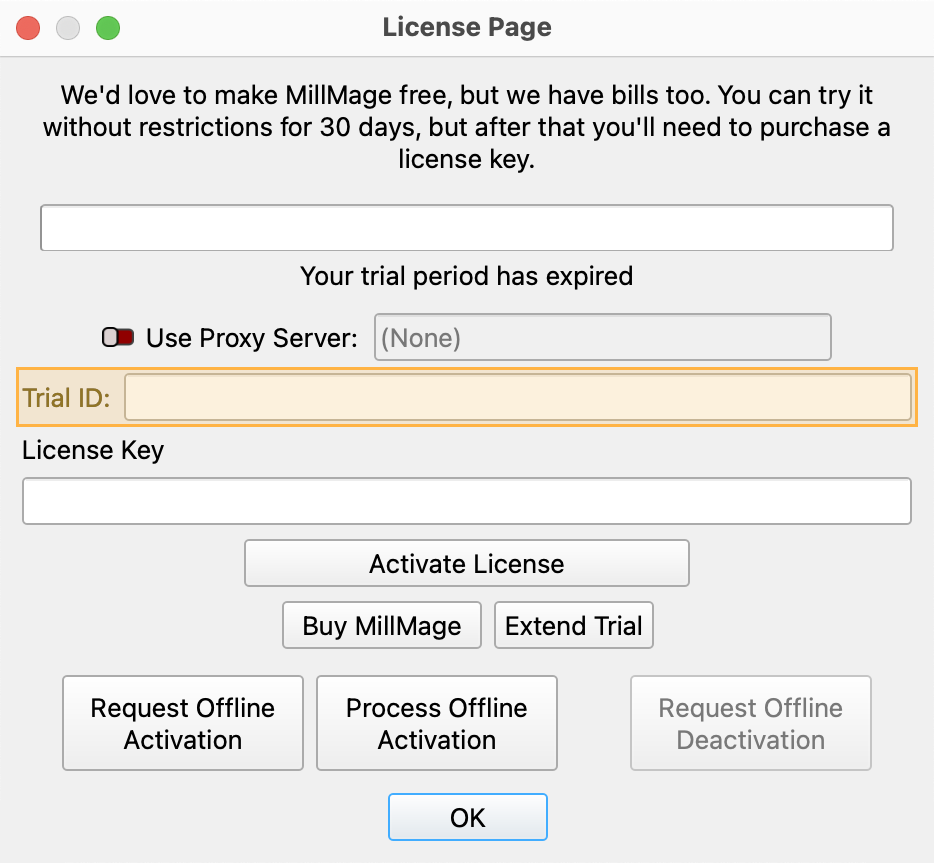

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Tool Library

The Tool Library is where you create and save entries containing information on the tools you'll use with your CNC.

When you create and edit operations, you'll be able to select a saved tool from your library, and MillMage will use the stored information for the chosen tool when calculating the toolpaths it sends to your CNC.

In order to create any operation, you'll need to have at least one tool in your Tool Library.

Create Your First Tool Library¶

-

Open the Manage Tool Library window by selecting CNC Tools → Tool Library in the menu bar.

-

Create a new Tool Library by selecting New Library.

-

Choose a memorable folder on your computer or network share to store the new tool library file. Name the file and select Save to save the new tool library file.

The location of the active tool library will now be displayed at the top of the Manage Tool Library window.

-

Create a new tool category by selecting the Create New Category button, and update the category name, such as "End Mills" in this example. Press Enter or click within the window to save the category name.

Tip

How you choose to organize your tools is up to you — you can organize by Tool Geometry, material type, or even machine, if you've got multiple CNC machines in your shop.

-

Create a new tool in the selected category by pressing the Create New Tool in Selected Category button.

-

Select the tool geometry from the dropdown list. Your selection affects the types of Operations you will be able to select to use with a given tool, and the appearance of the simulation in the Preview window.

Info

Tool Geometry¶

-

End Mills have sharp edges that cut material as the tool rotates and moves laterally (along the X and Y axes).

The bottom of a standard End Mill is flat with sharp corners, resulting in flat clearings, and sharp corners at the edges of cleared areas.

Some End Mills have rounded corners meeting at a flat surface, and produce flat clearings, but sloped corners at the edges of cleared areas. You can enter the radius of the rounded corner in the Corner Radius field of the Tool Properties section.

-

Ball Mills have completely rounded tips, resulting in rounded grooves with sloped edges where the tool has carved. Ball Mills are typically not used for clearing large areas.

-

V-Bits have angled tips that can create Chamfered edges, or angled grooves in material.

-

Drill bits have sharp tips to make vertical cuts (along the Z axis) into material.

-

Round-over bits have an inverted radius meeting at a tip, used to created rounded edges rather than sharp corners.

-

Scribe bits are used to precisely engrave a design by dragging its diamond coated tip over the surface of the material. Set the Spindle Speed to zero RPM as scribes do not need to rotate to function.

-

-

Populate the rest of the Tool Properties section with the dimensions and details available from your tool manufacturer. Available fields will change based on the tool geometry. Select Apply Changes to save the tool details.

Tool Details¶

Label Value Name User defined tool name Vendor Brand name or other sourcing information Tool Number Used on CNC machines with tool changers only Diameter Measurement of the cutting surface across the center of the rotating cutting edges — also known as the cutting diameter — with smaller diameter cutters creating tighter inside corners Flute Length Measurement of the cutting edges along the shaft of the tool — also known as the cut length # of Flutes The number of channels cut into the tool shaft that evacuate material chips from the workpiece Corner Radius Measurement of the tiny curve at the edge of the cutting surface to allow for cleaner floor corners. Set to zero for a square end mill with no corner radius Included Angle For V-bits and Drill bits only, the angle of the cutting edge as measured from the tool shank centerline Tip Length For Drill and Round-over bits only, the length of the cutting tip at the bottom of the tool Display Units The units of distance and speed that will display alongside the tool. Select Automatic to use your default MillMage settings, or Metric to display metric units Feeds and Speeds¶

The Feeds and Speeds saved to a given tool in your Tool Library are automatically entered in the Operation Settings Editor when you select that tool. You may make manual adjustments to these settings after a tool has been applied to an operation.

Label Value Feed Rate How quickly the tool moves through the material laterally along the X and Y axes during operations Plunge Rate The feed rate at which a tool is driven straight downwards — or plunged — into the workpiece in only the Z axis Ramp Feed The feed rate at which a tool is driven down into and across workpiece — used in moves down along the Z axis and over along the X and Y axes Spindle Speed (RPM) The rotational speed of the tool — Not all CNCs allow Spindle Speed control through software — some have routers which must be adjusted manually Chip Load This calculation shows the thickness of material removed by each cutting edge of a tool, during a single revolution of the spindle Spindle Advance For Drill bits only, this calculation shows the distance the spindle will move downward in the time it takes the tool to make on complete revolution, as determined by your Plunge Rate and settings Depth Per Pass The depth of material to be cleared with each pass of your router, with the total number of passes equal to Final Depth / Depths Per Pass Step Over The distance between each path of your chosen clearing pattern — a larger Step Over leads to greater distance between each path Step Over (%) The ratio of Diameter to Stepover value What Feeds and Speeds should I use?

The proper Feed and Speed settings depend on your tool, machine, material, and use case. In short: there's no easy answer that question.

For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

-

Continue adding your available tooling to the Tool Library. Select OK when finished to save the updated tool list and to close the Manage Tool Library window.

More Information¶

View the reference page for additional details: Tool Library

Next Steps¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.