Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

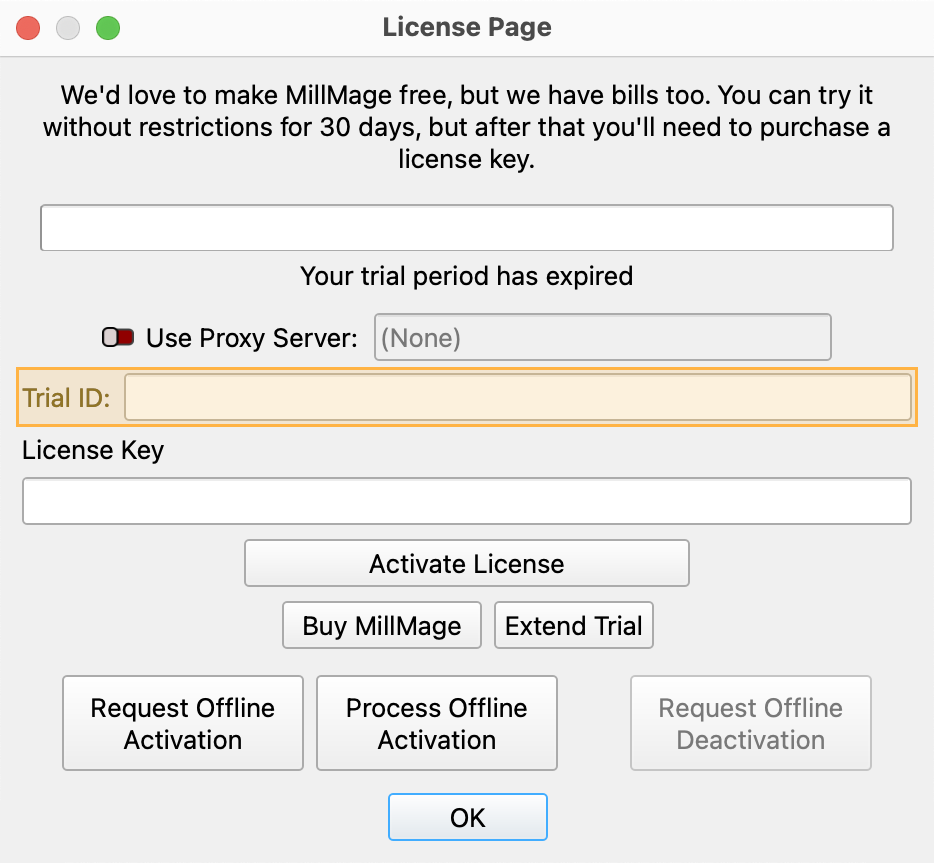

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Probing

Probing is the process of determining and setting the origin point on a workpiece, or measuring the length of a tool loaded into your CNC. Accurate and consistent probing leads to accurate and consistent results.

MillMage supports two types of automatic probing processes:

- XYZ Probing, which determines the zero point on your workpiece in up to three dimensions and applies an appropriate work offset.

- Tool Length Probing, which measures the length of a tool loaded into your CNC and applies an appropriate Z Axis offset. This is typically used after a tool change to update a Z Axis offset without re-zeroing on that axis.

In this guide, you'll see examples of both types of probing using CNC tools and accessories. Some CNC machines include built-in probing locations for Z Axis zeroing and tool length determination, while other models require additional accessories.

Because every CNC machine is different, and the material stock you use will vary with each project, the appropriate probing method may be different or unique to each project.

Probing Wizard Overview¶

MillMage includes a Probing Wizard that will walk you through setting up a probe block or tool length probe. First time Probing Wizard users must define the dimensions of the probe block or location of tool length probe before continuing with the probing wizard.

This page has a brief overview of the probing process, with more detailed guides available on the pages for each probe type.

Defining Probes¶

To define your probes, go to CNC Tools → Probe Settings, or click the Manage Probe Configuration button in the Probing Wizard.

Select either the XYZ Probe Block or the Tool Length Probe to edit.

XYZ Probe Block¶

An XYZ Probe Block sits on a corner of your workpiece and is used to define the workpiece origin. To set up a Probe Block:

- Use calipers to measure the offsets and enter them as Offset X, Offset Y, and Offset Z.

- Set the search distance – the distance the tool will travel in each axis while probing – in Search X, Search Y, and Search Z.

- Set the Probe Depth – the distance the tool will move below the surface of the probe when probing the X and Y axes.

- Set the probe feed rates.

For more information, see XYZ Probe Block.

Tool Length Probe¶

A Tool Length Probe measures the length of your tool, allowing you to use tool offsets when changing tools. To set up a Tool Length Probe:

- Set the location of the Tool Length Probe relative to the machine origin in Position X and Position Y.

- Set the Search Z value to the maximum distance the tool should travel downward when searching for the probe.

- Set the probe feed rates.

For more information see Tool Length Probe

Using Probes¶

Open the Probing Wizard by selecting CNC Tools → Probing Wizard, or by clicking the Probing button in the Move window.

Select the type of probe you'll be using.

XYZ Probe Block¶

PINCH DANGER

Keep fingers and hands away from the probing puck and/or tool during the probing process.

The CNC machine will keep moving the tool towards the puck or probe sensor until the machine is powered off, stopped by a hardware Emergency Stop, or successfully completes contact with the puck or probe.

Reminder & Quick Tip

Make sure that the puck or probing block is plugged into the CNC controller and that the tool lead is attached to the tool itself and not the collet, spindle, or router.

Use the probing block wires to keep the puck in place if it shifts during the probing process.

Quick How-to on using the probe block:

- Select the axes to probe.

- Use the jog and position controls to make sure your tool is at an appropriate location over the probe block.

- Enter the Tool Diameter if probing the XY axes and check other probing settings.

- Click the Execute X, Execute Y, or Execute Z button to probe a single axis, or Execute on All to probe all three axes, starting with Z.

- The origin in the workpiece coordinate space should now be set to the corner of your workpiece once complete.

For more information see XYZ Probe Block

Tool Length Probe¶

To use the tool length probe:

- Check that the travel path toward your Tool Length Probe is clear.

- Open the Probing Wizard

- Click Execute Tool Length Probe. MillMage will execute the GCode shown in the Probing Wizard window, moving the tool to the Tool Length Probe location and will run the probing routine.

Remember — because every CNC machine is different, the method of Z Axis probing you use depends on your CNC machine and available accessories.

For more information see Tool Length Probe

Detailed Probing Information¶

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.