Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

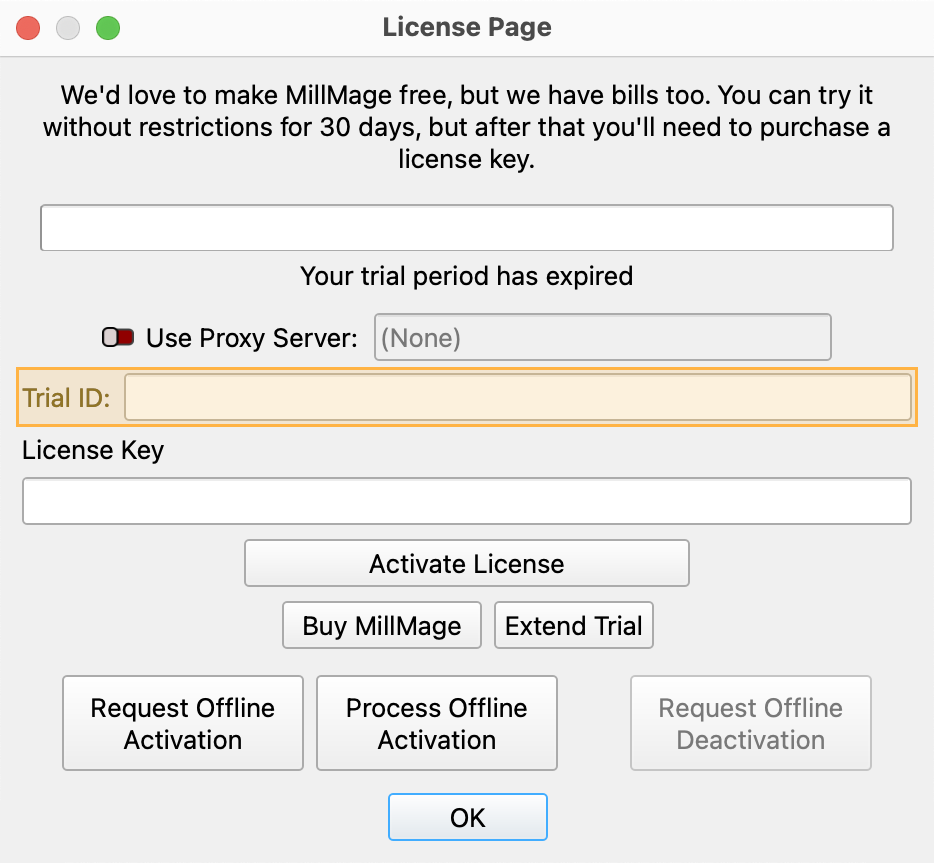

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

XYZ/Puck Probe Block

This guide explains the initial setup and use of a probe block to set the workpiece origin. Using a probe block isn't strictly necessary for basic CNC work – you can find and set your origin manually – but use of a probe block will provide more consistent and accurate results.

To follow this guide, you will need:

- A probe block compatible with your CNC machine — either Z axis only, or XYZ axis

- Calipers to measure the probe block (only for initial configuration)

How a Probe Block Works¶

A probe block is a metal block with a wire to connect to the CNC router's controller and another wire (usually ending in a magnet) that attaches the tool.

When the tool contacts the probe block, the electrical circuit is closed and a signal is sent to the controller to indicate that contact has been made.

Using the Probing Wizard, you will define your probe block dimensions and motion parameters. MillMage will move the tool toward the probe block until it touches, backs off, and then moves more slowly toward the block to touch it precisely. The process is first performed on the Z axis, then the X axis, and finally the Y axis. MillMage will automatically set the origin on each axis using the offsets entered in the Probe Settings.

If you've already set up the Probe Block, skip ahead to Probing and Setting the Origin.

Defining a Probe Block¶

Open the Probe Configuration window to define the parameters of your probe block by selecting either:

- CNC Tools → Probe Settings

- CNC Tools → Probing Wizard → Manage Probe Configuration

- Move Tab → Probing → Manage Probe Configuration

Update Settings¶

Select XYZ Probe Block to open the settings panel for that accessory. These settings help MillMage understand the shape of your probing block, and how to approach the block for probing.

Define your XYZ or Z axis probing pucks by carefully measuring your probing puck and updating MillMage with your puck dimensions in the Block/Puck settings panel. You will need:

- A probe block compatible with your CNC machine — either Z axis only, or XYZ axis

- Calipers to measure the probe block (only for initial configuration)

Click in the image below to jump directly to information on that section, or scroll down for information on each option.

Offset X, Offset Y, and Offset Z¶

Use calipers to measure the distance from the probe block's touch faces to the internal faces being measured and enter the values into these 3 boxes.

Leave Offset X and Offset Y set to 0 if using a Z axis only probing block.

Search X, Search Y, and Search Z¶

Enter the distance your tool will move after you manually position the tool over the probe block. The tool must be able to contact the probe block within these defined values you set here in order to succesfully probe.

If the tool does not make contact within this distance, an alarm will trigger on your controller, typically Alarm 9.

- Search Z is the distance the tool will move down seeking the probe block.

-

Search X and Search Y are the distances the tool will move to the left (X) or forward (Y) away from the block before lowering the tool and moving the same distance back toward the probe block until it makes contact.

Leave Search X and Search Y set to 0 if using a Z axis only probing block.

Probe Depth¶

The Probe Depth is the distance below the surface of the probe block to probe the sides of the block on the X and Y axes.

Set the Probe Depth to 0 if using a Z axis only probe block.

Probing Recommendations

Faster probe speeds may lead to damaged tooling, probes, and may lead to CNC operator injuries.

Start probing slowly (200 mm/min or less) to ensure that accurate contact is made. Pay attention during the probing process to make sure that your machine responds instantaneously on contact and that deflection does not occur. If long probing times are encountered, faster probing speeds can be explored in 50 mm/min increments.

Fast Probe Feed and Precise Probe Feed¶

- Fast Probe Feed is the initial speed at which the tool searches for the probe block, under 200 mm/min to start.

- Precise Probe Feed is a lower speed at which the tool will search for the probe block after initial contact. This movement will be a very short distance and should be kept to a fairly low speed for accuracy.

Precise Probe Distance and Backoff Distance¶

- Precise probe distance is the distance the tool will slowly move towards the probing contact point, set to 3.5 mm by default.

- Backoff distance is the length of movement the tool will slowly back away from the probing contact point, set to 1.5 mm by default.

Probing and Setting the Origin¶

Probing Checklist¶

1. Position Probe Block¶

Place the XYZ Probe Block on the front left corner of the workpiece. Ensure that the probe block is fully contacting the front and side faces of the material. If using a Z axis-only block, ensure it is laying flat on the material.

Typically, the probe block is plugged into the CNC router's control board, with a second wire attaching to the tool with a magnet or a clip. More advanced probe blocks may have an LED light to indicate contact.

Verify that the probe block is connected according to manufacturer directions.

2. Open the Probing Wizard¶

Open the Probing Wizard by selecting CNC Tools → Probing Wizard, or by clicking the Probing button in the Move Window.

Select XYZ Probe Block.

Unconfigured Probe Warning

Getting an error message with the following message?

Your Probe block is not yet configured. Please configure it before proceeding.

Follow the steps here to set up your probing block: Update Settings

3. Select Probing Axes¶

Select the axes you want to probe using your probe block. Turn off X and Y axis probing if using a Z axis only probing puck.

Select Next to continue.

4. Position Tool Over Probe Block¶

Use the jogging controls to position your tool over the Probe Block, ideally an inch or a centimeter above and near each face of the probe block. The tip of the tool must be within your user-set search distance. View the Move Window page for more information on the jogging controls.

The tool should be:

- All probe blocks: Over the surface of the probe block, and within the Z Search range of the surface.

- XYZ probe blocks: Positioned so that when searching in X and Y, it will move far enough away from the probe block face and come back. Make sure this travel path is clear of any obstructions.

If necessary, you can adjust the search distances on the next screen.

Select Next to continue.

5. Review Values¶

Some buttons aren't available!

If you're probing the Z Axis as well as the X and/or Y Axes, you may notice that the Execute on X and Execute on Y are initially greyed out and disabled. After probing the Z Axis, these buttons will be available.

Check and verify the current probing settings: - Search X/Y/Z — the distance the tip of the tool will travel along that axis to find the probing puck - XY Probe Depth — the depth below the top surface of the probing puck that the side of the tool will touch - Fast Probe Speed — faster than Precise Probe Speed - Precise Probe Speed — slower than Fast Probe Speed

6. Set Tool Diameter¶

Set Tool Diameter to the diameter of the tool you're using to probe. This allows MillMage to adjust the searching distance offset to account for the size of the tool.

7. Verify Probing Block Positioning and Setup¶

Make sure your Probe Block is connected to your controller correctly, that the probe block placement is snug and in position.

Probing Recommendations

Faster probe speeds may lead to damaged tooling, probes, and may lead to CNC operator injuries.

Start probing slowly (200 mm/min or less) to ensure that accurate contact is made. Pay attention during the probing process to make sure that your machine responds instantaneously on contact and that deflection does not occur. If long probing times are encountered, faster probing speeds can be explored in 50 mm/min increments.

8. Execute Probing¶

To probe an individual axis, click on Execute on Z, on X, or on Y.

To probe all three axes (Z first, followed by X and Y), click on Execute on All.

MillMage will execute the probing routine and set the workpiece origin.

9. Probing Complete¶

Select Next to close the Probe Wizard. Your work origin is now set, and you can jog the tool and begin sending Operations to your CNC machine.

CNC machines with a Tool Length Probe will need to run the Tool Length Probing routine next.

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.