Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

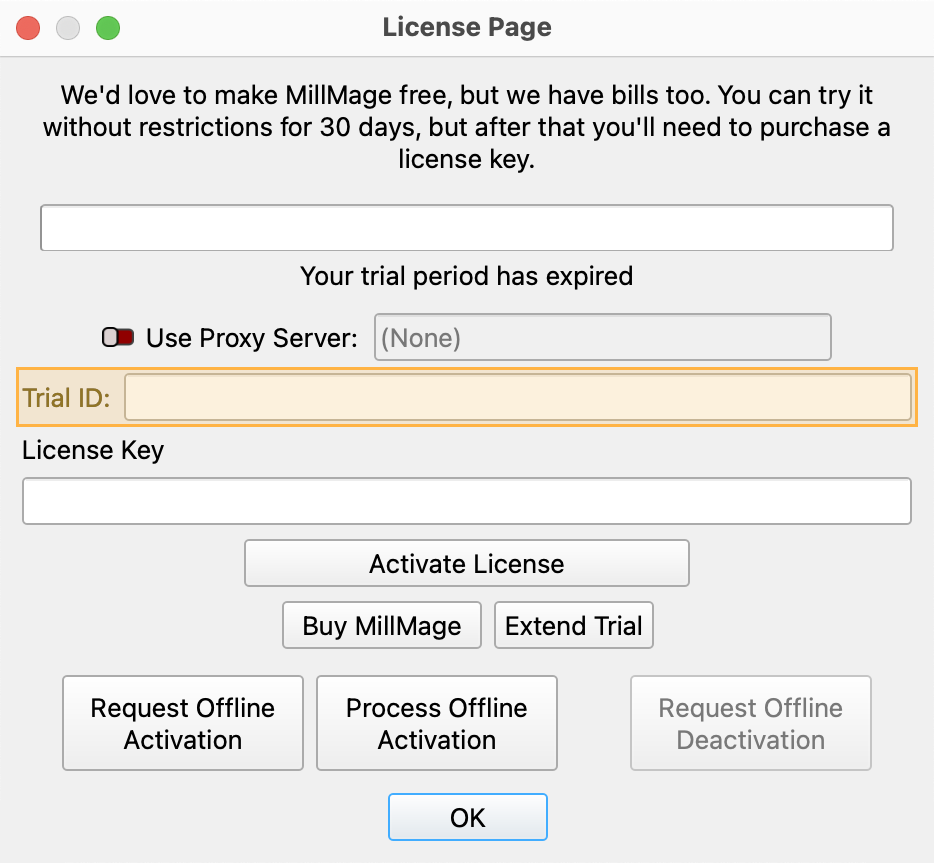

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Center Finder

Quick Reference: Center Finder

-

Location

CNC Tools → Center Finder

The Center Finder is a tool for finding the center of circular stock, as well as defining that stock in your MillMage Workspace.

By jogging your CNC machine tool head to three positions on a circle (or other regular shape), and setting those positions in the Center Finder Wizard, MillMage can calculate the circle that passes through those three points, jog your CNC machine to its center, and create a circle in your MillMage Workspace matching those dimensions, to represent your stock.

The Center Finder is available in the CNC Tools Menu.

Using the Center Finder¶

First Steps¶

- Home your machine.

- If your machine does not have homing switches, make sure to start the machine with the tooling at the 0,0 point of its work area — that is typically the lower left corner for GCode-based devices.

- Secure the material stock to prevent it from moving during the center-finding operation.

Set the Points¶

Point 1¶

Jog the tool head to the first position on the edge of your circle, as shown in the wizard, then click Set First Circle Point.

Warning

You must jog the tool head with the Move control panel or from the Move Window. Center Finder will not work if you move the tool head by hand.

Point 2¶

Jog the tool center to the next position on the edge of your circle, as shown in the wizard, then click Set Second Circle Point.

Point 3¶

Jog the tool center to the last position on the edge of your circle, as shown in the wizard, then click Set Third Circle Point.

Align to Center¶

Move to Center¶

The last step will show you the calculated center of your circle and allow you to jog to that point.

Create Guide Circle¶

Toggle on Add Guide Circle to Project to create a circle on the T1 Tool layer, that will provide a representation of your stock in your MillMage Workspace.

Set Origin¶

See Project Setup and Project Setup Wizard for more information on setting project or work origin.

Notes¶

-

You can set the points in any order, and they do not need to be positioned exactly as shown in the reference photos — they need only be far enough apart from one another along the perimeter of the shape that they are valid for calculating the center. The reference photos are meant as guidelines for acceptable distance.

-

This tool can find the center of any shape that can be described with a circle diameter:

Error Messages¶

Unable to Query the Current Position of the Machine¶

This happens when MillMage is unable to get the position of the tool center from the controller.

-

Often, the CNC machine is still moving, or another command is still in process. Click OK, and try again after waiting a few seconds.

-

If the warning persists, make sure the controller is still connected and is showing Ready at the top of the Job Control Window. If you are unable to connect, see Troubleshooting: Connection Problems.

Not Enough Separation Between Points¶

You have not moved the tool center away from the last point or have not moved it far enough to make an acceptable calculation.

-

Try moving farther away and setting the point again.

-

You must jog the tool head using its control panel or the Move Window, and not by hand.

Unable to Calculate Center¶

MillMage can't calculate center, or it would be outside your CNC machine's work area.

-

This typically happens on machines without homing switches that were not manually homed properly.

-

Verify the material stock dimensions in Project Setup and the Project Setup Wizard.

-

Restart your machine with the head at your machine origin and try to run the wizard again.

Cannot Move to Calculated Center¶

MillMage is not able to move the CNC machine tool head.

-

Make sure the controller is connected to MillMage and is showing Ready at the top of the Job Control Window. If you are unable to connect, see Troubleshooting: Connection Problems.

-

Verify that the CNC machine/controller power switch is on and plugged into external power, as some controllers can be powered through an active USB connection — providing enough energy to power on the controller but not enough to move the motors.

Troubleshooting¶

-

The accuracy of the Center Finder depends on the accuracy of your point placement. One trick is to try to split the dot on the edges of your stock.

-

If you set a point incorrectly, hit the Reset button. This will clear all points saved. After, restart from the current point. You can set the points in any order.

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.