Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

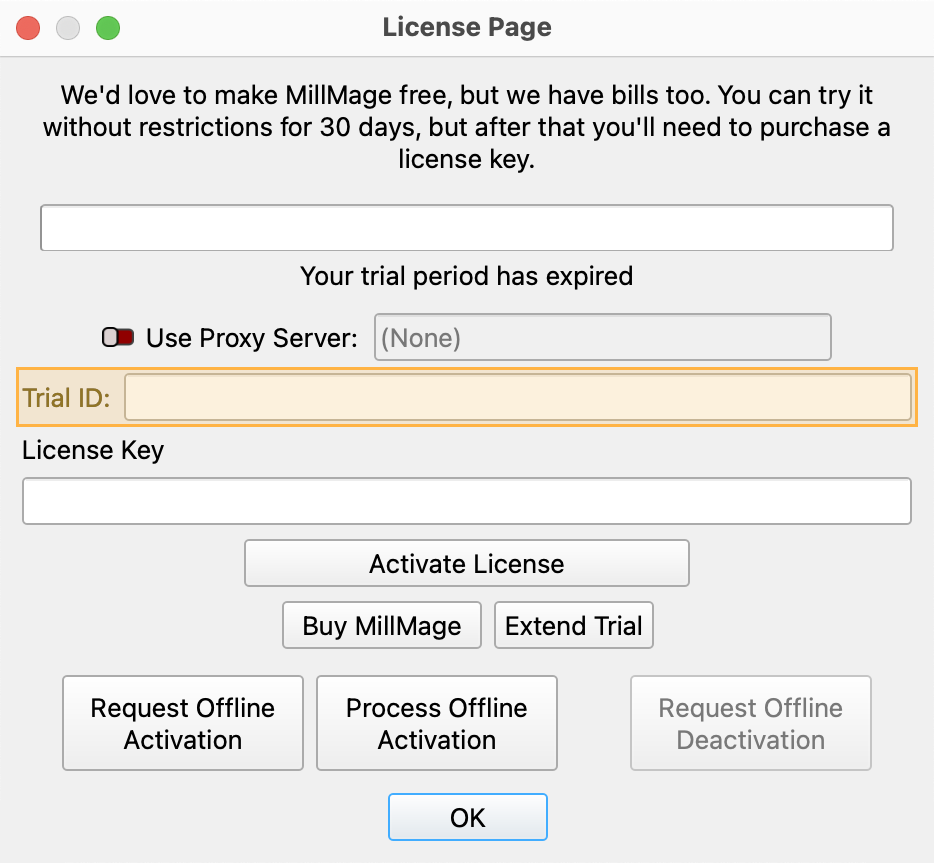

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Coordinates and Origin

Understanding and working within your CNC's coordinate systems is necessary to successfully jog your CNC around its work area and tell it where to cut or carve your project on your workpiece.

MillMage displays the current tool position relative to two coordinate systems: Machine Coordinates and Workpiece Coordinates. The top of the Move Window displays the position of the tool in relation to both the machine and workspace coordinate space.

Coming from LightBurn?

See MillMage for LightBurn Users for a detailed comparison.

Tool Position Display¶

- Tool Position (M) is the position of the tool relative to the entire area of the machine. This coordinate system will be consistent regardless of the size or origin of the workpiece between projects.

- Tool Position (W) is the position of the tool relative to the workpiece defined in Project Setup and by zeroing out the axes in the Position Tab tab of the Move Window. This coordinate system will vary between projects.

There are a few ways to tell MillMage where to output your project within the work area of your machine, each available in the Project Setup Wizard.

Machine vs Workpiece Position

MillMage displays the current tool position relative to two coordinate systems: Machine Coordinates and Workpiece Coordinates. The Position tab in the Move Window has a toggle to select which coordinate system to use for positioning.

- Machine Position is the position of the tool relative to the entire area of the machine. This coordinate system will be consistent regardless of the size or origin of the workpiece between projects.

- Workpiece Position is the position of the tool relative to the workpiece defined in Project Setup and by zeroing out the axes in the Move Window's Position. This coordinate system will vary between projects.

Machine Coordinates¶

The machine coordinate system is an absolute coordinate system based on the entire work area of the CNC machine selected in Devices. Some uses for this coordinate system include:

- Defining the location of a Tool Length Probe or automatic tool changer.

- Working with a jig or fixture secured in a known location on the bed of the CNC machine.

- Moving around the bed of the machine before setting the zero point of the Workpiece Coordinate system.

To position the tool using machine coordinates, make sure that the Workpiece toggle in the Position tab of the Move Window is unselected.

Users coming from LightBurn should be aware that although this is similar in many ways to LightBurn's absolute coordinates, the MillMage Workspace does not reflect the full work area of the CNC machine selected — it's defined by the size of the workpiece in Project Setup.

Workpiece Coordinates¶

The workpiece coordinate system is based on the size and origin location of the workpiece set up in Project Setup and is reflected in the MillMage Workspace.

To position the tool using workspace coordinates, make sure that the Workpiece toggle in the Position tab of the Move Window is selected.

Use the workpiece coordinate system to position artwork and the CNC router relative to the workpiece, regardless of its location on the bed of the CNC router.

Positioning Output¶

There are two steps to telling your CNC where to cut or carve your project on your workpiece — setting the Project Origin, and then Zeroing your machine at the correct location.

Project Origin and Zero Point¶

Output is always positioned relative to a location on your workpiece chosen during Project Setup — one of four corners, or the center point. This location is them Project Origin — also known as the work offset — the (0,0) point for the X (left/right), and Y (front/back) Axis on the material stock.

Any artwork you place in the MillMage grid will be output in the corresponding location on your stock, relative to that shared 0,0 point.

You'll also need to select either Top or Bottom as the Zero Point during project setup. This is the height at which you'll Zero the Z Axis — either the surface of your stock (Top) or the surface of your wasteboard (Bottom).

Zeroing Axes¶

After you've defined the Project Origin and Zero Point in Project Setup, and before you start your job, you also need to tell your machine where those locations are in physical space.

There are two ways to do that in MillMage:

- Jog your CNC to the correct location and then press the Zero X/Y/Z buttons in the Move Window.

- If your machine supports it, use the Probing Wizard to automatically zero each axis.

Accurate zeroing — especially in the Z dimension — is necessary to make certain your router carves where you expect it to, not into your wasteboard, and doesn't collide with workholding equipment in the CNC's bed, or crash into its sides.

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.