Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

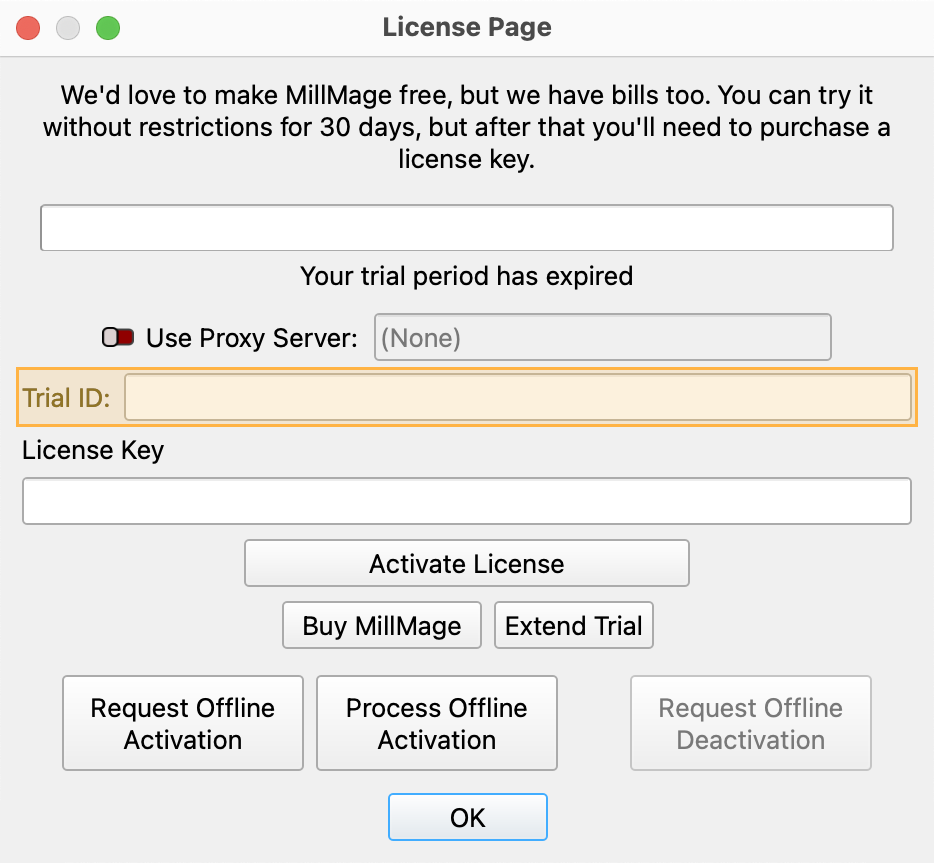

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Device Settings: Basic Settings

The Basic Settings tab of Device Settings contains the most commonly used CNC settings.

Click any option in the image below to jump directly to the relevant section for that option, or scroll down for a full list of options and descriptions.

The Basic Settings tab of Device Settings

Working Size¶

The maximum X (Width) and Y (Height) travel for your machine.

These values do not affect the dimensions stored in your machine's firmware, or the size of your MillMage Workspace, which is instead determined by your Project Setup parameters.

Zero Point Configuration¶

Set your machine's zero point/origin in this section. The arrows in the diagram show the directions of the axes.

Tip

Remember that your machine origin is separate from your workpiece origin.

MillMage displays the current tool position relative to two coordinate systems: Machine Coordinates and Workpiece Coordinates. The Position tab in the Move Window has a toggle to select which coordinate system to use for positioning.

- Machine Position is the position of the tool relative to the entire area of the machine. This coordinate system will be consistent regardless of the size or origin of the workpiece between projects.

- Workpiece Position is the position of the tool relative to the workpiece defined in Project Setup and by zeroing out the axes in the Move Window's Position. This coordinate system will vary between projects.

Device Units¶

These are the units your device uses internally, not the units used for designing artwork or controling your machine from MillMage. These units are set when you add your machine and can be left alone unless they're set incorrectly.

To change your design units or control units, see Settings & Preferences, Move Window, or Numeric Edits.

Design Units and Control Units

By default, control units — the units used for speed and distance when controlling your device — are linked with design units — the units used when designing in MillMage. Changing either one between millimeters and inches will automatically change the other.

To unlink the two types of units, use the Unit Linking Toggle in the Move Window.

Other Options¶

Enable $J Jogging¶

Newer versions of GRBL (1.1f and later) can use this custom jogging mode. Enable this setting to add a Continuous Jog switch to the Move Window. After also enabling Continuous Jog in the Move Window, you'll be able to hold an arrow key to begin jogging in a direction, and release to stop (cancel) the move.

$J Jogging (Continuous Jog) has several benefits over normal jogging:

- It does not affect the GCode parser state.

- If soft limits are enabled, jog commands that would go out of bounds are ignored without triggering an error or alarm.

- It allows for cancelling a jog move.

Enable DTR signal¶

This setting controls whether MillMage sends a Data Terminal Ready signal to the controller to start serial communication. Many programmable hobby-level controllers, including Arduino-based systems, use the DTR pin to reset the controller. If your machine's controller won't communicate, toggling this setting may help.

Enable 'Out of Bounds' warning¶

Enable this setting to have MillMage warn you if a job will cause your machine to travel out of bounds, as determined by the stock dimensions you enter in Project Setup.

Query regularly for tool position¶

This setting is enabled by default. When it's enabled, MillMage will regularly check the tool position to update the tool position display in the Move Window

Enable Job Checklist¶

When this setting is enabled, MillMage will display a text box with a list of items whenever you Start a job. This is typically used as a reminder of things that need to be done before starting the job, such as turning on a dust extractor or putting on protective glasses.

To create a custom checklist, click the Edit button.

Video: Job Checklists

LightBurn Video

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

S-value Max¶

This setting tells MillMage how to represent 100% spindle speed when creating GCode for your machine.

This value needs to match what your controller expects. MillMage will default to the most common value for the type of controller you selected when you created your device.

If you are directly connected to your machine, you can verify that the default value matches your controller's expectation by going to CNC Tools → Machine Settings and checking the Maximum spindle speed / $30 setting.

Baud Rate¶

This setting controls the speed at which MillMage attempts to communicate with your machine's controller.

MillMage defaults to 115,200 baud for GRBL controllers and 250,000 baud for Marlin controllers. Some Marlin controllers use 115,200 baud, and some GRBL controllers go as low as 9600 baud. If you are having trouble communicating with your controller and are certain the controller and firmware are supported, contact the manufacturer for the correct baud rate for the board, which may be different from the default value.

Transfer Mode¶

MillMage defaults to the Buffered Transfer mode for communication with GRBL devices. This is faster and more reliable than the Synchronous Transfer mode. However, there are a few devices that are incompatible with Buffered Transfer mode. These devices will stutter, stop, or even restart when buffered communication is selected. If you notice this happening, try switching the Transfer mode to Synchronous.

Troubleshooting¶

- If you aren't seeing a setting you expected to see, check which tab you're in and make sure it's applicable to your machine.

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.