Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

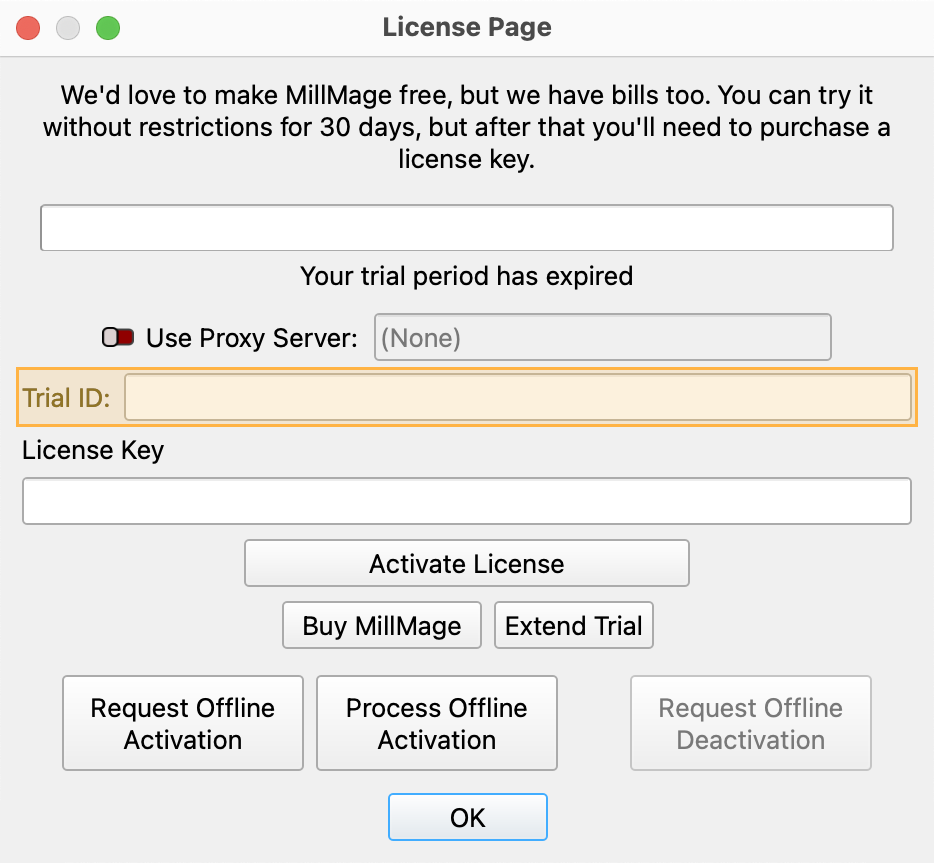

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Job Control Window

The Job Control Window is the hub for setting up and selecting a CNC machine, Framing and Starting jobs, saving/loading GCode, and more.

Accessing the Job Control Window¶

The Job Control Window is located in the bottom right-hand corner of MillMage by default. If you have closed the Job Control Window, go to Window → Job Control to re-enable it. To restore it and all other windows to their default positions, go to Window → Reset to Default Layout.

Tip

The layout of MillMage is highly customizable. For more information on enabling and disabling windows and toolbars, or rearranging the default layout, see Customizing the MillMage Window.

Job Control Window Options and Settings¶

The type of CNC machine you have active and certain options in the Settings window — including enabling Beginner Mode — will affect the way the Job Control Window looks.

WARNING

CNC MACHINES CAN CAUSE SEVERE INJURIES. ALWAYS FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND GUIDELINES WHEN OPERATING A CNC MACHINE.

ALWAYS WEAR PROPER EYE, EAR, AND BODY PROTECTION WHEN OPERATING A CNC MACHINE.

CNC MACHINES MAY START OPERATING WITHOUT HUMAN INTERACTION. TAKE APPROPRIATE PRECAUTIONS BEFORE ENTERING THE WORK AREA.

ROTATING SHAFTS CAN CAUSE SEVERE INJURY. KEEP AWAY FROM THE SHAFT WHEN OPERATING.

DO NOT WEAR JEWELRY OR LOOSE-FITTING CLOTHING WHILE NEAR THE SHAFT.

DO NOT LEAVE A RUNNING CNC MACHINE UNATTENDED.

ALWAYS HAVE A PHYSICAL EMERGENCY STOP (E STOP) FOR YOUR CNC MACHINE. THE STOP BUTTON IN MILLMAGE MUST NOT BE YOUR ONLY METHOD OF STOPPING A CNC MACHINE.

ALWAYS HAVE APPROPRIATE FIRE SUPPRESSION READILY AVAILABLE.

Click any option in the image below to jump directly to the relevant section for that option, or scroll down for a list of options and descriptions.

Start¶

WARNING

CNC MACHINES CAN CAUSE SEVERE INJURIES. ALWAYS FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND GUIDELINES WHEN OPERATING A CNC MACHINE.

ALWAYS WEAR PROPER EYE, EAR, AND BODY PROTECTION WHEN OPERATING A CNC MACHINE.

CNC MACHINES MAY START OPERATING WITHOUT HUMAN INTERACTION. TAKE APPROPRIATE PRECAUTIONS BEFORE ENTERING THE WORK AREA.

ROTATING SHAFTS CAN CAUSE SEVERE INJURY. KEEP AWAY FROM THE SHAFT WHEN OPERATING.

DO NOT WEAR JEWELRY OR LOOSE-FITTING CLOTHING WHILE NEAR THE SHAFT.

DO NOT LEAVE A RUNNING CNC MACHINE UNATTENDED.

ALWAYS HAVE A PHYSICAL EMERGENCY STOP (E STOP) FOR YOUR CNC MACHINE. THE STOP BUTTON IN MILLMAGE MUST NOT BE YOUR ONLY METHOD OF STOPPING A CNC MACHINE.

ALWAYS HAVE APPROPRIATE FIRE SUPPRESSION READILY AVAILABLE.

Commands your CNC machine to immediately begin running your current project. Operations listed in the Operations Window will be performed sequentialy if more than one operation is set to output and assigned to shapes.

Pause¶

Sends a pause command to the CNC controller to momentarily interrupt a running job. Click the Resume button to continue a paused job.

Pause and Stop From the Keyboard

While your CNC machine is running, you can use your keyboard's Pause key to Pause the CNC machine and Ctrl+Break to Stop it. Break is typically on the same key as Pause, but more compact keyboards may not have this key.

Stop¶

Sends an abort command to the CNC controller to stop the currently running job. You can recover stopped jobs using the Start Here feature in the Job Preview Window.

Warning

Always have a physical emergency stop (E stop) for your CNC machine. The stop button in MillMage mut not be your only method fo stopping a CNC machine.

Review Safety and Warnings for additional warnings.

Framing¶

WARNING

CNC MACHINES CAN CAUSE SEVERE INJURIES. ALWAYS FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND GUIDELINES WHEN OPERATING A CNC MACHINE.

ALWAYS WEAR PROPER EYE, EAR, AND BODY PROTECTION WHEN OPERATING A CNC MACHINE.

CNC MACHINES MAY START OPERATING WITHOUT HUMAN INTERACTION. TAKE APPROPRIATE PRECAUTIONS BEFORE ENTERING THE WORK AREA.

ROTATING SHAFTS CAN CAUSE SEVERE INJURY. KEEP AWAY FROM THE SHAFT WHEN OPERATING.

DO NOT WEAR JEWELRY OR LOOSE-FITTING CLOTHING WHILE NEAR THE SHAFT.

DO NOT LEAVE A RUNNING CNC MACHINE UNATTENDED.

ALWAYS HAVE A PHYSICAL EMERGENCY STOP (E STOP) FOR YOUR CNC MACHINE. THE STOP BUTTON IN MILLMAGE MUST NOT BE YOUR ONLY METHOD OF STOPPING A CNC MACHINE.

ALWAYS HAVE APPROPRIATE FIRE SUPPRESSION READILY AVAILABLE.

Use the two Frame buttons to preview the position of the job in your CNC machine's work area, by commanding the CNC machine to use the tool head to trace a path around the area where your project will output.

The speed at which the CNC machine travels during Framing is determined by the value set in the Speed field in the Move Window.

Frame Continuously¶

Enable Frame Continuously in the Basic Settings tab of Device Settings to command your CNC machine to run the Framing path repeatedly, until you tell it to stop. Framing Continuously is often helpful when adjusting material positioning in your CNC machine's work area.

Bounding Box Frame  ¶

¶

Commands the CNC machine to trace a path defined as the smallest possible rectangle that will fully contain all graphics you're sending to the CNC machine.

Rubber Band Frame  ¶

¶

Traces the smallest possible path that fully contains all graphics in the design you're sending to the CNC machine, as if a rubber band were stretched around them.

Tip

Rubber Band Framing is useful for lining up jobs with irregular shapes where a box outline doesn't fit well. For example, a long, thin diagonal shape, or a triangle.

Save GCode¶

Saves your current project as a GCode file. You can manually adjust the input a file extension along with the file's name as you save it, or you can set a default file extension in the Custom GCode tab of the Device Settings window.

If you do not have a default file extension set in the Custom GCode tab,MillMage will always save files with the last extension you manually input. If you never manually input a file extension, MillMage will save your file with the .gc extension.

You can transfer this file to your machine to run it without ever having to directly connect using MillMage by saving the file to a networked or portable drive.

These options are also available in the File Menu.

Run GCode¶

WARNING

CNC MACHINES CAN CAUSE SEVERE INJURIES. ALWAYS FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND GUIDELINES WHEN OPERATING A CNC MACHINE.

ALWAYS WEAR PROPER EYE, EAR, AND BODY PROTECTION WHEN OPERATING A CNC MACHINE.

CNC MACHINES MAY START OPERATING WITHOUT HUMAN INTERACTION. TAKE APPROPRIATE PRECAUTIONS BEFORE ENTERING THE WORK AREA.

ROTATING SHAFTS CAN CAUSE SEVERE INJURY. KEEP AWAY FROM THE SHAFT WHEN OPERATING.

DO NOT WEAR JEWELRY OR LOOSE-FITTING CLOTHING WHILE NEAR THE SHAFT.

DO NOT LEAVE A RUNNING CNC MACHINE UNATTENDED.

ALWAYS HAVE A PHYSICAL EMERGENCY STOP (E STOP) FOR YOUR CNC MACHINE. THE STOP BUTTON IN MILLMAGE MUST NOT BE YOUR ONLY METHOD OF STOPPING A CNC MACHINE.

ALWAYS HAVE APPROPRIATE FIRE SUPPRESSION READILY AVAILABLE.

Use this option to load and run a file previously saved in the appropriate format for your type of CNC machine. To use this option, MillMage must be directly connected to your CNC machine.

Home¶

WARNING

CNC MACHINES CAN CAUSE SEVERE INJURIES. ALWAYS FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND GUIDELINES WHEN OPERATING A CNC MACHINE.

ALWAYS WEAR PROPER EYE, EAR, AND BODY PROTECTION WHEN OPERATING A CNC MACHINE.

CNC MACHINES MAY START OPERATING WITHOUT HUMAN INTERACTION. TAKE APPROPRIATE PRECAUTIONS BEFORE ENTERING THE WORK AREA.

ROTATING SHAFTS CAN CAUSE SEVERE INJURY. KEEP AWAY FROM THE SHAFT WHEN OPERATING.

DO NOT WEAR JEWELRY OR LOOSE-FITTING CLOTHING WHILE NEAR THE SHAFT.

DO NOT LEAVE A RUNNING CNC MACHINE UNATTENDED.

ALWAYS HAVE A PHYSICAL EMERGENCY STOP (E STOP) FOR YOUR CNC MACHINE. THE STOP BUTTON IN MILLMAGE MUST NOT BE YOUR ONLY METHOD OF STOPPING A CNC MACHINE.

ALWAYS HAVE APPROPRIATE FIRE SUPPRESSION READILY AVAILABLE.

Commands your CNC machine to execute a homing cycle, during which it moves toward the home position looking for the switches that activate when it hits the boundary.

Homing is how your CNC machine locates its 0,0,0 position along the X, Y, and Z Axis position, and all subsequent positioning information is determined relative to that point.

Warning

Do not use this button if your CNC machine does not have homing switches. If you are unsure, contact your CNC machine's manufacturer.

Show Last Position¶

Places a cross-hair cursor in the Workspace at the last reported location of the CNC machine head. If you jog the CNC machine within MillMage using any of the positioning tools, the position will be updated.

The position does not update live — for example, it will not update while a job is running. Live updating might encourage some users to watch the screen rather than their CNC machine — CNC machines should never be left unattended while running.

Devices¶

Opens the Devices window, where you can create, remove, or edit device profiles for CNC machines you want to use with MillMage.

Right-clicking the Devices button closes and re-opens the connection to the currently selected device.

See Devices for more information.

Serial Ports Dropdown¶

MillMage will attempt to automatically select the correct serial port and connect to your CNC machine, but you may need to manually select it from this dropdown. When connected, the Disconnected message in the top left corner of the Job Control Window will change to Ready. If you are using a GCode-based CNC machine, you will see a startup message in the Console window.

You may need to right-click the Devices button in theJob Control Window to refresh the list of available ports.

If you're having trouble connecting to your CNC machine, see Troubleshooting: Connection Problems.

Device Selection Dropdown¶

If you've created multiple device profiles for multiple CNC machines, select the CNC machine you are currently working with the dropdown menu.

Device Status¶

The readout in the top left of the Job Control Window indicates the current status of the CNC machine.

-

Disconnected indicates that the CNC machine is not connected to MillMage.

-

Ready indicates that the CNC machine is connected to MillMage and ready to receive commands.

-

Busy indicates that the CNC machine is connected to MillMage and actively completing a process.

The progress bar indicates the percentage of commands that have been streamed to the CNC machine, along with a time estimate indicating how long the CNC machine has been streaming, and how much longer it will continue streaming. These estimates can be close to the total runtime of the project, but are not identical.

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.