Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

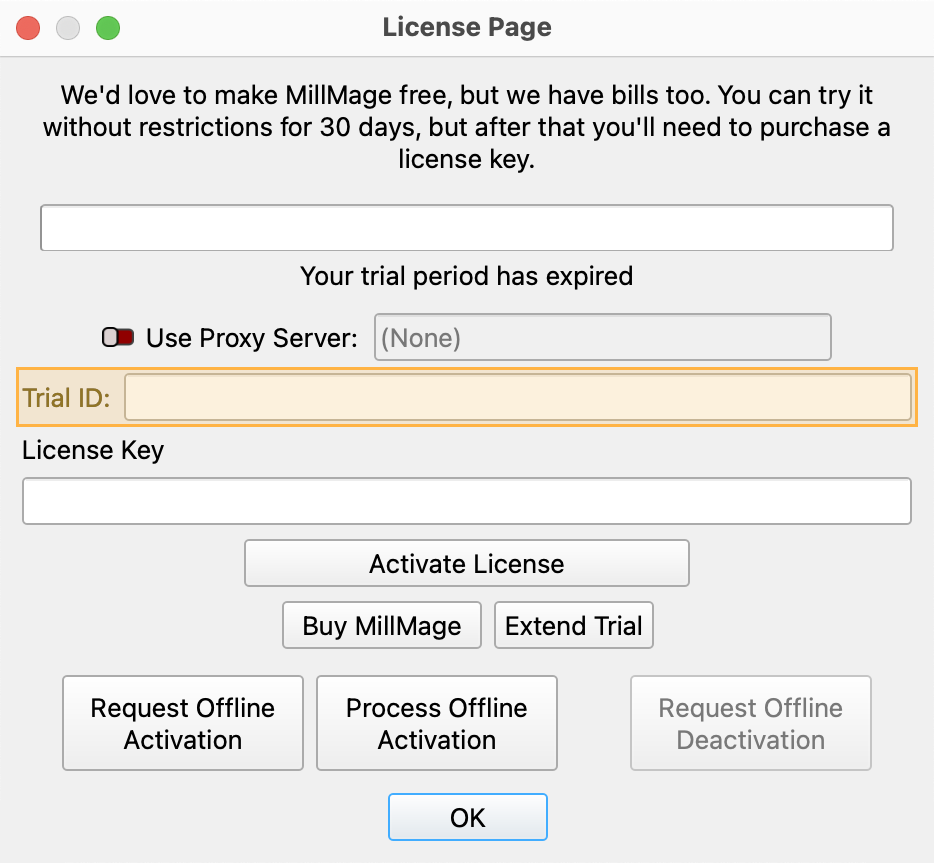

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Drill

Drill operations tell your router to carve in a straight down motion. Depending on the type of the Drill operation and your settings, you can command your router to carve a hole cleanly through your material, mark a spot on the material, or bore a Countersink hole into its surface.

Drill operations are always located at the center of the individual shapes they are assigned to, regardless of the size of the shape. In other words, if you assign a Drill operation to a circle, the location of the carving will be the same regardless of whether the circle has a 5 mm diameter or a 50 mm diameter, provided the center of each circle is the same. Assigning non-circular shapes to Drill operations will result in a drilling operation in the center of the shape's selection box.

Drill Mode Settings¶

Click any option in the image below to jump directly to the relevant section for that option, or scroll down for a list of options and descriptions.

Sections that have special settings for Drill operations are listed just below, while common settings that apply similarly to most or all other types of operations are listed toward the bottom.

Note

For information on options that are unique to other types of operations, see Other Operations, below.

Operation Type¶

Plunge¶

Plunge the tool directly down into the material, beginning at your specified Start Depth and continuing without pausing until it reaches your specified Final Depth.

Peck¶

Peck works similarly to Plunge, but instead of advancing continually until , the router will advance in increments defined by your specified Depth Per Pack value, retract between each peck to either the height of your material, or to a set Distance, and then advance again by the Depth Per Peck value until it reaches the Final Depth.

Spot¶

Spot moves the tool down only to just below the surface of your material, to mark a spot on its surface.

All Depths and Entry parameters are unavailable when you select Spot.

Countersink¶

When using Countersink, you can specify a Hole Diameter, which MillMage will use along with the included angle of your selected tool to calculate the depth required to create a hole of that diameter.

Pattern Preview¶

Depths and Entry¶

The available Depths and Entry settings change depending on the Operation Type you have selected. If a setting does not apply to your selected Operation Type, it will be grayed out and unadjustable.

Equation Support and Automatic Unit Conversion

The Depths and Entry/Steps fields in the Operation Settings Editor support equations and automatic unit conversion.

For example:

-

To cut to a final depth of ¼ in, type

1/4in the Diameter field, then click in another field, and MillMage will convert to the value to0.75.Addition (

+), subtraction (-), and multiplication (*), are all also supported. -

If your display units are set to metric but you've taken measurements in imperial, you can enter

1/4 inand MillMage will convert the value to6.350 mm. This works in reverse as well, converting metric units to imperialMultiple notations are supported, including

ft,',", andmm.

Start Depth¶

The depth, relative to the surface of your stock, at which the operation will begin carving or cutting.

Final Depth¶

The depth, relative to the surface of your stock, at which the operation will stop carving or cutting.

Final Depth is the total depth of the material that will be removed from your stock.

Peck Settings¶

The following settings apply only to Drill operations set to Peck.

Depth Per Peck¶

The amount of distance your router will advance before retracting.

After retracting the router will lower again and advance again by the Depth Per Peck distance, and repeat this process until it reaches the Final Depth.

Dwell Time¶

The amount of time the router will spend at the bottom of each peck (defined by the Depth Per Peck setting), before retracting.

Retract Type¶

Select Above material to tell your router to retract above the surface of your material between each peck.

Select Distance to assign a height relative the bottom of each peck, to retract the router to.

Retract Rate¶

Determines the speed at which the router will retract between each peck.

Retract Distance¶

The height to which the router will retract, relative to the bottom of the current peck.

In other words, if your router is drilling a 20 mm deep hole with 4 pecks of 5 mm each, and you set Retract Distance to 5 mm, the router will retract to 0 (the surface of your material) after the first peck, then to 5 mm beneath the surface of your material after the second peck, and so on.

Hole Diameter¶

Available for Countersink operations only. MillMage uses this value along along with the included angle of your selected tool to calculate the depth required to create a hole of established diameter.

Common Settings¶

Click here for information on settings that apply similarly to all types of operations

Name¶

Use this field to edit the display name of the operation in the Operations Window. By default, all operations will be named according to their type.

Paint Color¶

Click the Paint Color button to open the Select Color window, which controls the color by which the operation will be indicated in the Preview window, if Show paint colors is enabled.

You can choose from a number of Basic Colors presented at the top left of the window, or create a custom color.

To create a custom color:

-

Press Pick Screen Color to hover your cursor over any color on your screen. Click to select the color you're hovering over.

-

Use the color gradient and shading slider at the top right.

-

Adjust numeric or hexidecimal values at the bottom right to create a custom color.

-

After creating a custom color, click Add to Custom Colors to save it for future use.

Click OK to apply the color to your operation, or Cancel to exit the window thout applying the color.

Output¶

Controls whether the operation will be sent to your CNC when you Preview your project, press the Start button in the Job Control Window, or save your project in GCode format.

Auto Use Layer¶

Enable this switch to automatically apply this operation to all shapes set to a given layer. Designate the layer by clicking the button to the right of the switch.

Note

When Auto Use Layer is enabled, you can still Assign Operations to graphics set to any other layer, as normal, but all graphics assigned to the chosen layer will also have the Operation applied to them.

Tool Setup¶

Select Tool¶

Press the Select Tool button to open your Tool Library and select a tool to assign to the operation.

MillMage will automatically filter for appropriate tools for the type of operation you've selected. Some operations require specific tool geometries — if a tool's geometry is not appropriate for the type of operation you've selected, it will be unlisted and not selectable.

Tool Information¶

The remaining fields in this section display information about your selected tool, as entered in the Tool Library.

Tool Name¶

The name you gave the chosen tool in the Tool Library.

Diameter¶

The diameter of the cutting edge of your tool.

Cut Length¶

The length of the cutting edge of the chosen tool, from the top to the bottom of all flutes.

# of Flutes¶

The number of flutes on the chosen tool.

Vacuum and Coolant¶

Enable Vacuum¶

Enable this setting to automatically turn on your vacuum system when this operation begins.

This option requires a vacuum system that is connected to your CNC's controller.

Enable Coolant¶

Enable this setting to automatically turn on your coolant system when this operation begins.

This option requires a coolant system that is connected to your CNC's controller.

Feeds and Speeds¶

The Feeds and Speeds saved to a given tool from your Tool Library are automatically entered in the Operation Settings Editor when you select that tool.

What Feeds and Speeds should I use?

The proper Feed and Speed settings depend on your tool, machine, material, and use case. In short: there's no easy answer that question.

See Feeds and Speeds for an overview of these settings and their interactions

For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

Spindle Speed¶

Controls the speed at which your router will rotate your tool.

Note

Not all CNCs allow Spindle Speed control through software. Some have routers which must be adjusted manually.

Plunge¶

Controls the speed at which your CNC will move along the Z Axis during plunge movements.

Feed Per Revolution¶

The Feed Per Revolution calculation shows the distance the tool advances into the material with each revolution of the spindle.

Feed Per Revolution = Plunge Rate / Spindle Speed (RPM)

The optimal Feed Per Revolution varies according to your tool and material. For specific recommendations, the best resource is usually the manufacturer of your machine or tool.

Vacuum and Coolant¶

Enable Vacuum¶

Enable this setting to automatically turn on your vacuum system when this operation begins.

This option requires a vacuum system that is connected to your CNC's controller.

Enable Coolant¶

Enable this setting to automatically turn on your coolant system when this operation begins.

This option requires a coolant system that is connected to your CNC's controller.

Other Operations¶

All types of operations are listed below. Select an operation to learn more about the settings available for that type of operation.

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.