Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

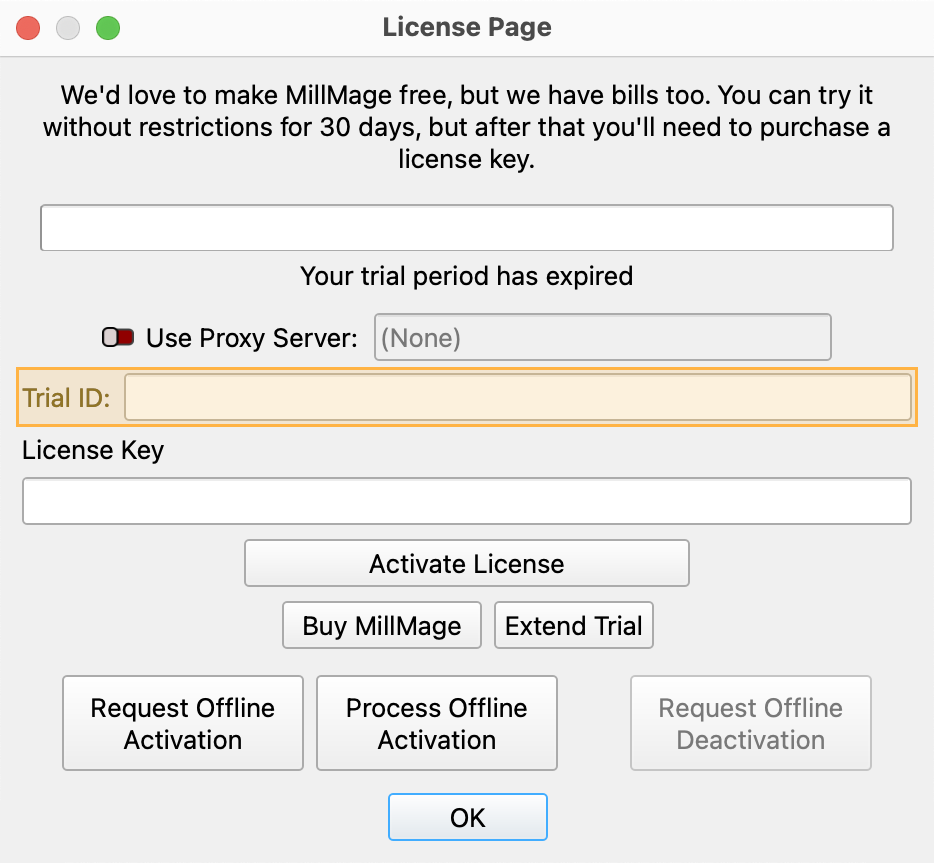

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Warning

Secure the material stock to the CNC machine by following the CNC manufacturer workholding guidelines.

FAILURE TO FOLLOW CNC MANUFACTURER WORKHOLDING RECOMMENDATIONS CAN LEAD TO DAMAGED PROPERTY, BODILY HARM, OR DEATH.

Verify that the material stock is properly secured by vigorously pushing and pulling against the workpiece in all directions.

View the Workholding Guide for examples.

Workholding

In this guide you'll see several examples of mounting material stock securely onto your CNC machine.

The goal of all workholding is:

- Active engagement

- Movement prevention of both the workpiece and the product of every CNC operation

- Ensuring that nothing moves free unless acted upon by the user with that intention

Good workholding prevents unplanned movements.

Because every CNC machine is different, and the material stock being used for each project will vary, the workholding method you choose may be different or unique to each project.

For some setups, the workpiece — or material stock — can be screwed directly into the CNC machine's sacrificial wasteboard, while other machines will require the use of clamps that slide into T-shaped tracks, are screwed into threaded inserts, or even inserted into custom jigs. Always secure the material stock to the CNC machine by following your CNC manufacturer's workholding guidelines.

How secure is secure?

You should be able to vigorously push and pull against the workpiece in all directions once the material stock has been secured to the CNC machine.

Choosing a Workholding Method¶

The most suitable workholding solution for your project depends entirely on:

- the CNC machine you have

- the size and type of material you're machining

- the complexity of your project

- the operations, tooling, and Feeds and Speeds you've chosen

- your experience with your equipment

Always consider safety, efficiency, and the specific requirements of your machining tasks when selecting a workholding method.

Always Preview the operations set to output before starting the job or sending the GCode to the CNC machine.

Workholding Examples¶

Below we showcase a variety of methods for securing workpieces on a CNC router, each with their own advantages and limitations. The most suitable solution will depend on factors such as the type of material you're machining, the complexity of your project, and available resources.

Remember — because every CNC machine is different, we're not going to teach you all about CNC workholding. We're going to introduce you to several common methods and their pros/cons instead.

Warning

Secure the material stock to the CNC machine by following the CNC manufacturer workholding guidelines.

FAILURE TO FOLLOW CNC MANUFACTURER WORKHOLDING RECOMMENDATIONS CAN LEAD TO DAMAGED PROPERTY, BODILY HARM, OR DEATH.

Verify that the material stock is properly secured by vigorously pushing and pulling against the workpiece in all directions.

View the Workholding Guide for examples.

Workholding Optimizations¶

Related Topics¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.