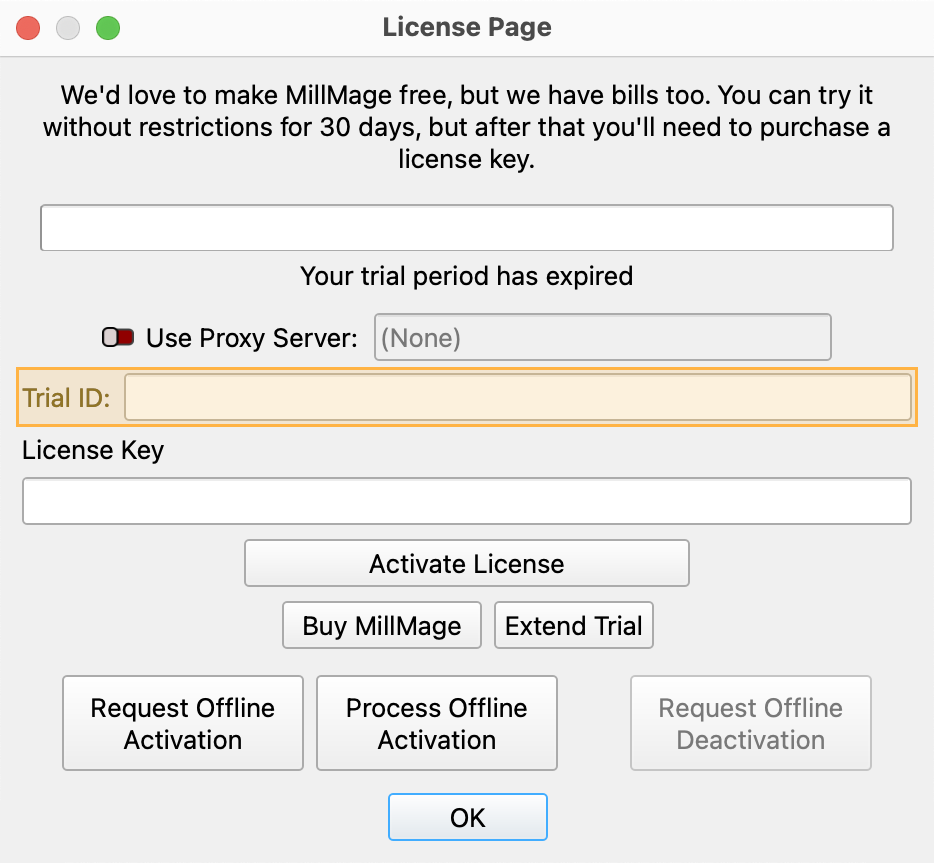

Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to [email protected] to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

MillMage for LightBurn Users

If you're new to MillMage, but are an experienced user of our sister software, LightBurn, you'll see a lot in MillMage that's very familiar.

All of the design tools you're used to are here, exactly where you expect them to be. But, due to the differences in running a laser versus a CNC router, there are also several crucial differences between using LightBurn and MillMage.

On this page, we'll go over the most important differences to keep in mind as you make the transition.

Warning

The current version of MillMage is intended for experienced CNC users. This documentation provides information on using MillMage, but you will need prior knowledge of CNC fundamentals and best practices in order to safely and effectively operate your machine. If you're a CNC beginner, consult your machine's manufacturer for resources on getting started with your specific hardware.

Several factors that MillMage does not control impact the kinds of things you'll be able to make and the quality of your results, including the capabilities of your machine, the type of material you're working with, individual workflow decisions, and even ambient conditions in your workshop.

Project Setup¶

Every time you open MillMage, you'll see the Project Setup Window.

If you close out of either window without saving project parameters, MillMage will also close.

That's because MillMage needs to know certain information about your project in order to function. These parameters include Stock Dimensions and Thickness, Project Origin, Zero Point and several other important settings.

It's ok to enter arbitrary parameters if you just want to explore MillMage, or design graphics without setting up and assigning operations, but it is crucial that you accurately complete this setup before you run a job or export GCode from your project.

If this information isn't accurate, your job won't run the way you're expecting it to, and you might ruin your material or damage your machine.

Go to File → Project Setup Edit to reopen the editor or wizard at any time, and adjust your project parameters.

Workspace¶

The bounds of your Workspace grid — the area where you create and edit graphics — are set differently in LightBurn and MillMage.

In LightBurn, your Workspace represents the size of your laser's physical work area, and this doesn't change from project to project.

MillMage sets the Workspace bounds to the dimensions of the material stock or workpiece that will be loaded into a CNC machine, instead of the available CNC working area. These are the same dimensions you enter in Project Setup, so your Workspace will have different dimensions each time you use stock of different size.

Operations vs. Layers¶

In LightBurn, different colors indicate different layers. These colors differentiate each operation needed to complete a job.

While different colors also indicate different layers in MillMage, unlike in LightBurn they're only visual indicators that you can use when creating and organizing your designs, and don't have any effect on the output to your CNC (with one important caveat, covered below).

Instead, you will need to create operations in the Operations Window, then select the shapes you'd like those operations to apply to, and click Assign Shapes.

When you select an operation in the Operations Window, the shapes you've assigned to it will show with a bold outline in your Workspace.

Auto-Use Layer¶

If you prefer the LightBurn workflow for applying operations to shapes based on layer color, there's a special option in the Operation Settings Editor in MillMage that allows you to do so.

You can enable Auto Use Layer for any operation, and MillMage will automatically apply that operation to every shape on the chosen layer.

Job Positioning¶

In LightBurn, you can choose between three positioning modes that determine the location of output in your laser's work area — an absolute coordinates system, one relative to your laser's location when you start a job, and a user-set custom origin.

In MillMage, output is always positioned relative to a location on your workpiece chosen during Project Setup — one of four corners, or the center point. You'll need to position your router over the corresponding location in the physical work area, and zero both the X and Y dimensions at that spot.

You'll also need to select either Top or Bottom as the Zero Point during project setup, and zero the router at that location in the Z dimension before starting the job.

You can accomplish that by manually jogging your router to the correct location on your workpiece and using the Zero buttons in the Move Window, or, if your machine supports it, you can use the Probing Wizard to Zero each axis through an automated process.

Accurate zeroing — especially in the Z dimension — is necessary to make certain your router carves where you expect it to, not into your wasteboard, and doesn't collide with workholding equipment in the CNC's bed, or crash into its sides.

Workholding¶

Warning

Secure the material stock to the CNC machine by following the CNC manufacturer workholding guidelines.

FAILURE TO FOLLOW CNC MANUFACTURER WORKHOLDING RECOMMENDATIONS CAN LEAD TO DAMAGED PROPERTY, BODILY HARM, OR DEATH.

Verify that the material stock is properly secured by vigorously pushing and pulling against the workpiece in all directions.

View the Workholding Guide for examples.

The need for workholding is one of the main factors that separates CNC routers and laser cutters, regardless of the software you use.

Lasers apply almost no force when cutting or engraving material — as long as your material is heavy enough not to move due to air assist or machine resonance, you can generally place your material in the laser's bed and run the job without worrying about it moving.

With CNCs, the force applied to your material is considerable while cutting or carving, and without proper care to secure the material to your CNC, it will move. That will not only ruin your project, it's also extremely dangerous.

Workholding is the practice of securing your material stock to your CNC.

The goal of all workholding is:

- Active engagement

- Movement prevention of both the workpiece and the product of every CNC operation

- Ensuring that nothing moves free unless acted upon by the user with that intention

Good workholding prevents unplanned movements.

Because every CNC machine is different, and the material stock being used for each project will vary, the workholding method you choose may be different or unique to each project.

Checkout our Workholding guide to learn about the strengths and drawbacks of several different workholding methods.

Consider this guide a starting point, and always refer to your CNC manufacturer's instructions for information on the recommended workholding method for your machine and material, before starting any job.

Related Topics¶

- Project Setup Edit

- Project Setup Wizard

- Workspace

- Operations Window

- Operations Setting Editor

- Move Window

- Workholding

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.